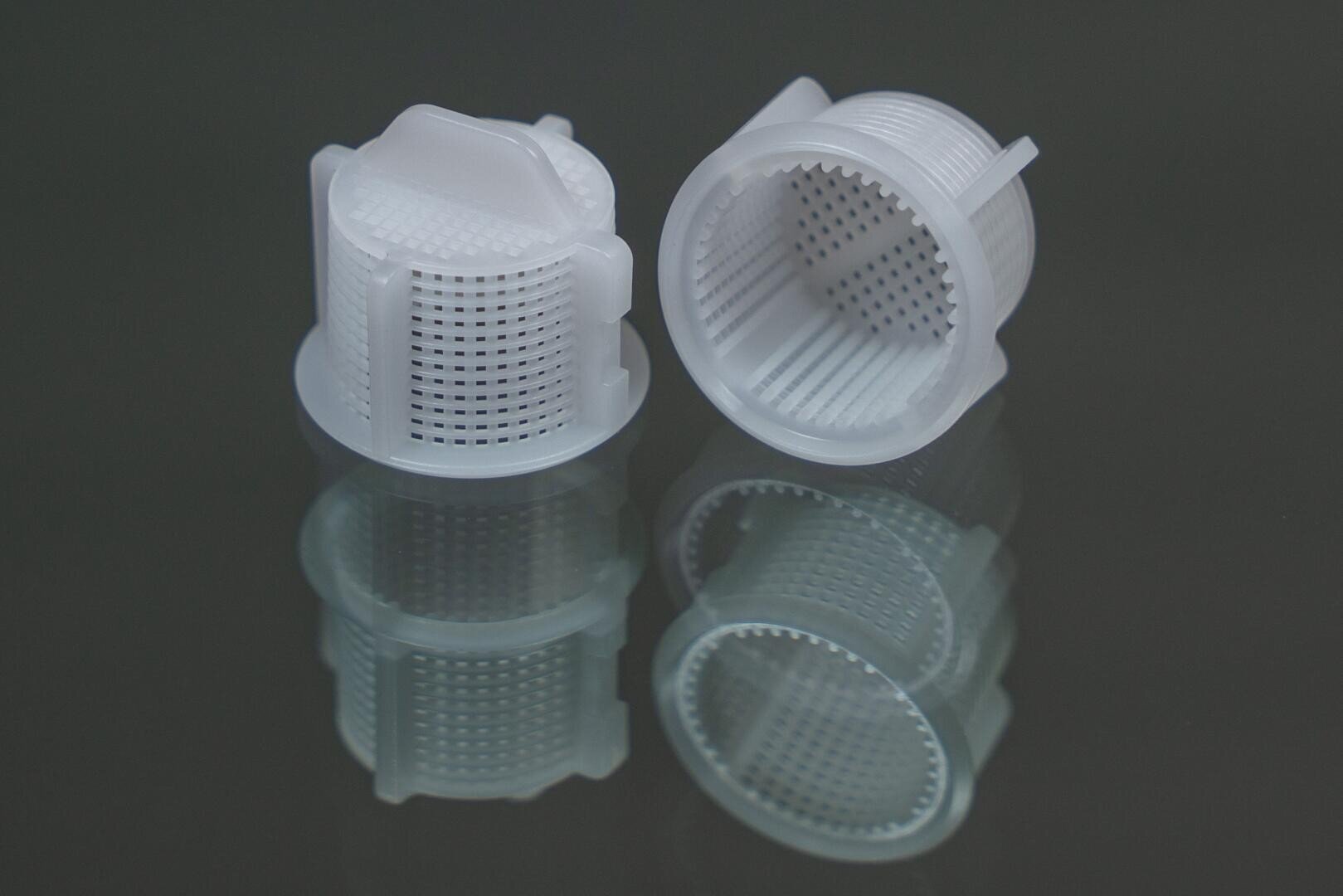

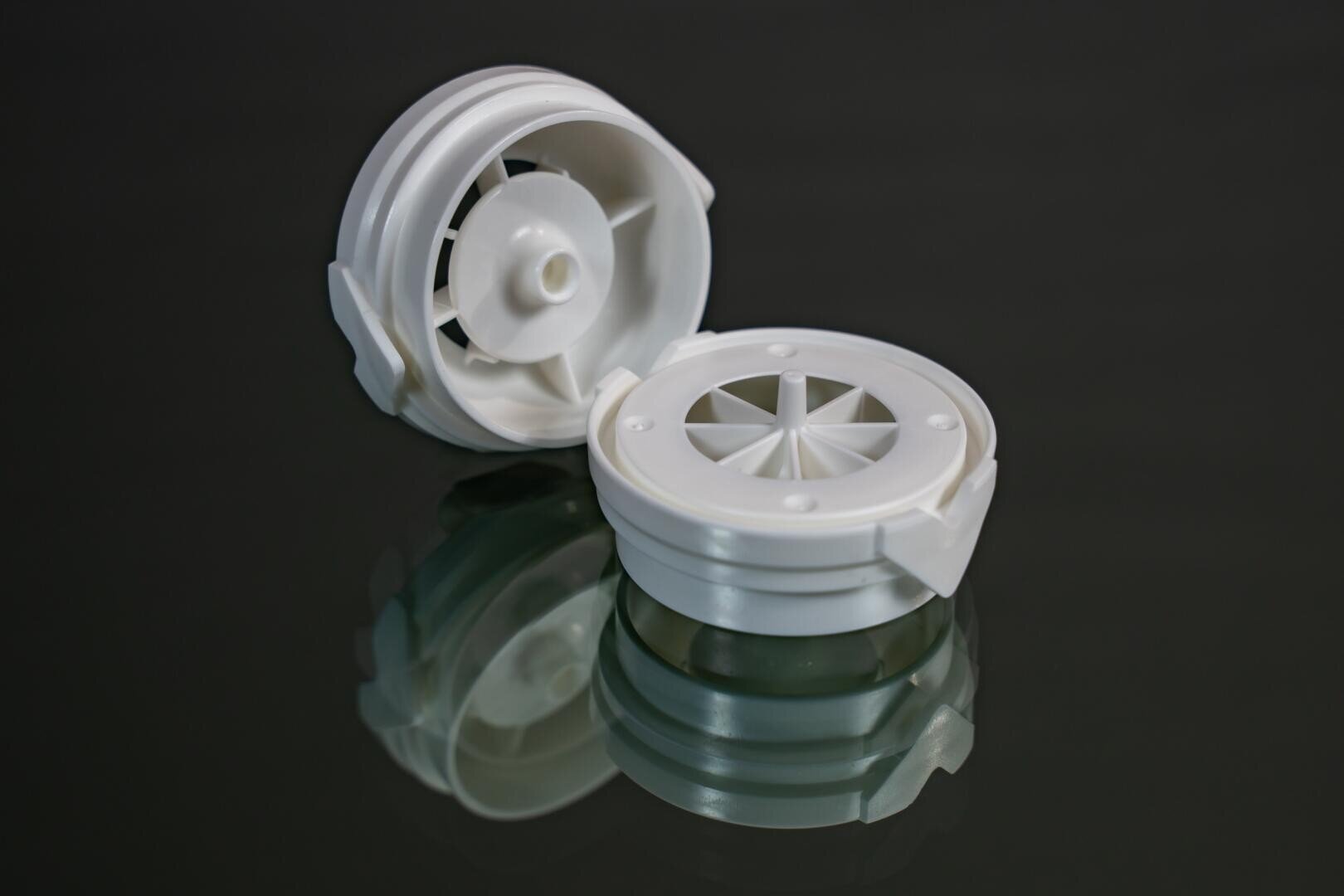

Precision injection moulded parts for demanding applications

elfo ag produces high-precision plastic injection parts for medical and other industries. Advanced tooling, long experience, and reliable processes ensure components with top dimensional accuracy, excellent surface quality, and consistent reproducibility.

Diverse applications

Our precision injection moulded parts are used in numerous applications – from medical devices to complex functional parts. Typical requirements are:

- Precise part design for maximum functionality

- Complex geometries with tight tolerances

- Cost-effective series production with high quantities

Material expertise

Polymers are used across the entire spectrum – from standard plastics such as PE and PP to high-performance polymers such as PPS or PEEK. These are specifically tailored to the function, mechanical and thermal requirements, and regulatory specifications.

Customer benefits for medical technology applications

Our customers benefit from a continuous co-engineering process – from the concept phase to series production:

- Optimised part design: Geometries are tailored to the injection moulding process and ensure reliable and economical production.

- Suitable material selection: Plastic materials are specifically designed for the respective application.

- Precision: Maximum manufacturing accuracy guarantees reproducible part geometries.

- High process stability: Early feasibility assessments ensure efficient series production.

- Advance quality planning: Using methods such as process flow diagrams (PF), process failure mode and effects analysis (P-FMEA) and production control plans (PLP), we ensure that regulatory requirements and customer specifications are reliably met.

- Process validation: For medical technology applications, we support validation activities in accordance with current standards. These include IQ (Installation Qualification), OQ (Operational Qualification) and PQ (Performance Qualification). This ensures that the injection moulding process is demonstrably stable, reproducible and compliant with regulations.

With this combination of precision, validated processes and material diversity, elfo ag offers reliable precision injection moulded parts – even for sensitive applications with the highest quality requirements, such as those demanded in medical technology.

Here you can learn more about precision injection moulded parts and see examples of completed projects: Precision plastic parts | elfo ag

Contact us for a consultation regarding your application:k.berwert@elfo.ch