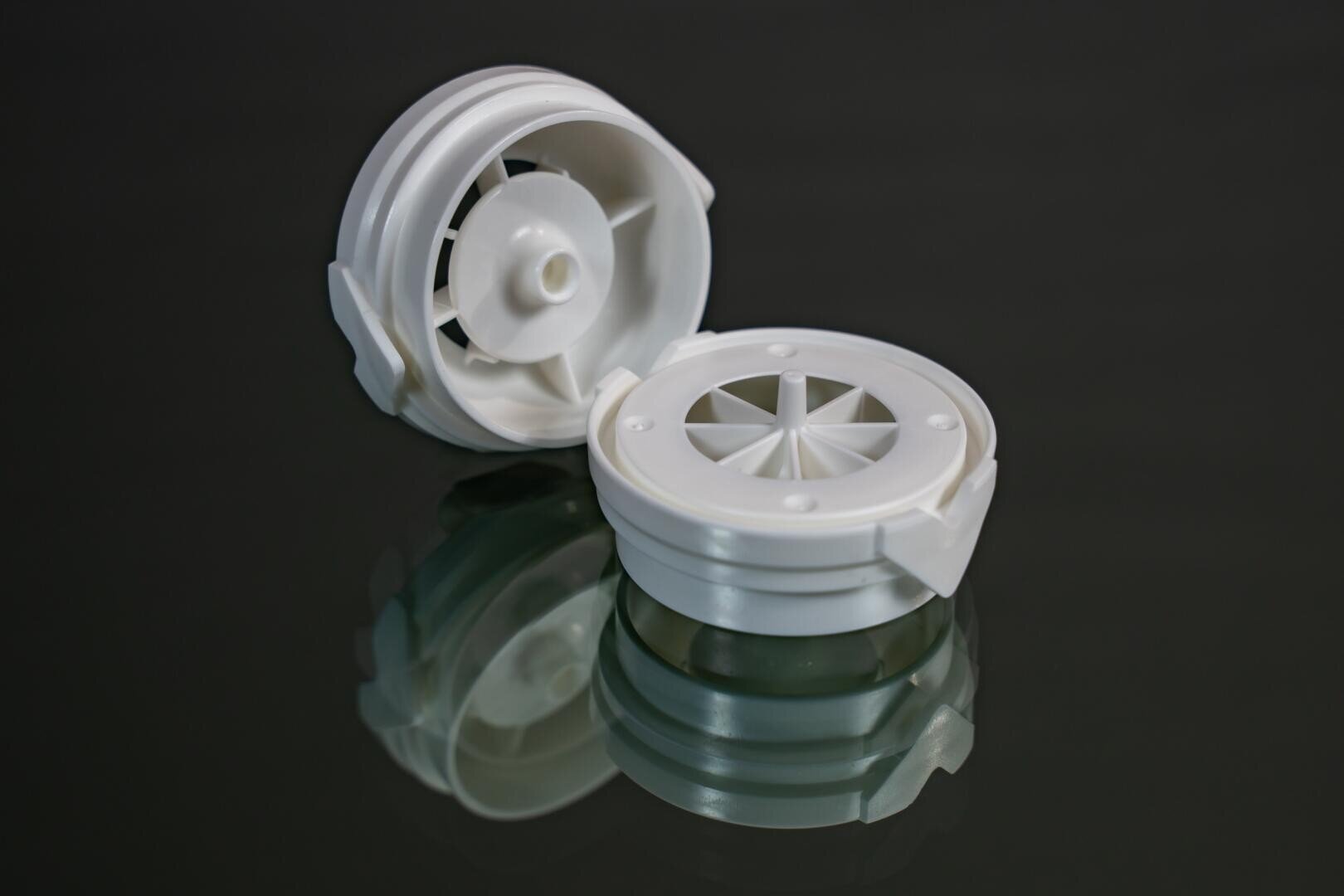

When precision takes shape – plastic injection moulding reimagined

A seal that seals perfectly. A connection that fits seamlessly. A function that only works reliably when every detail is right. This is where our passion for precision begins.

The challenge

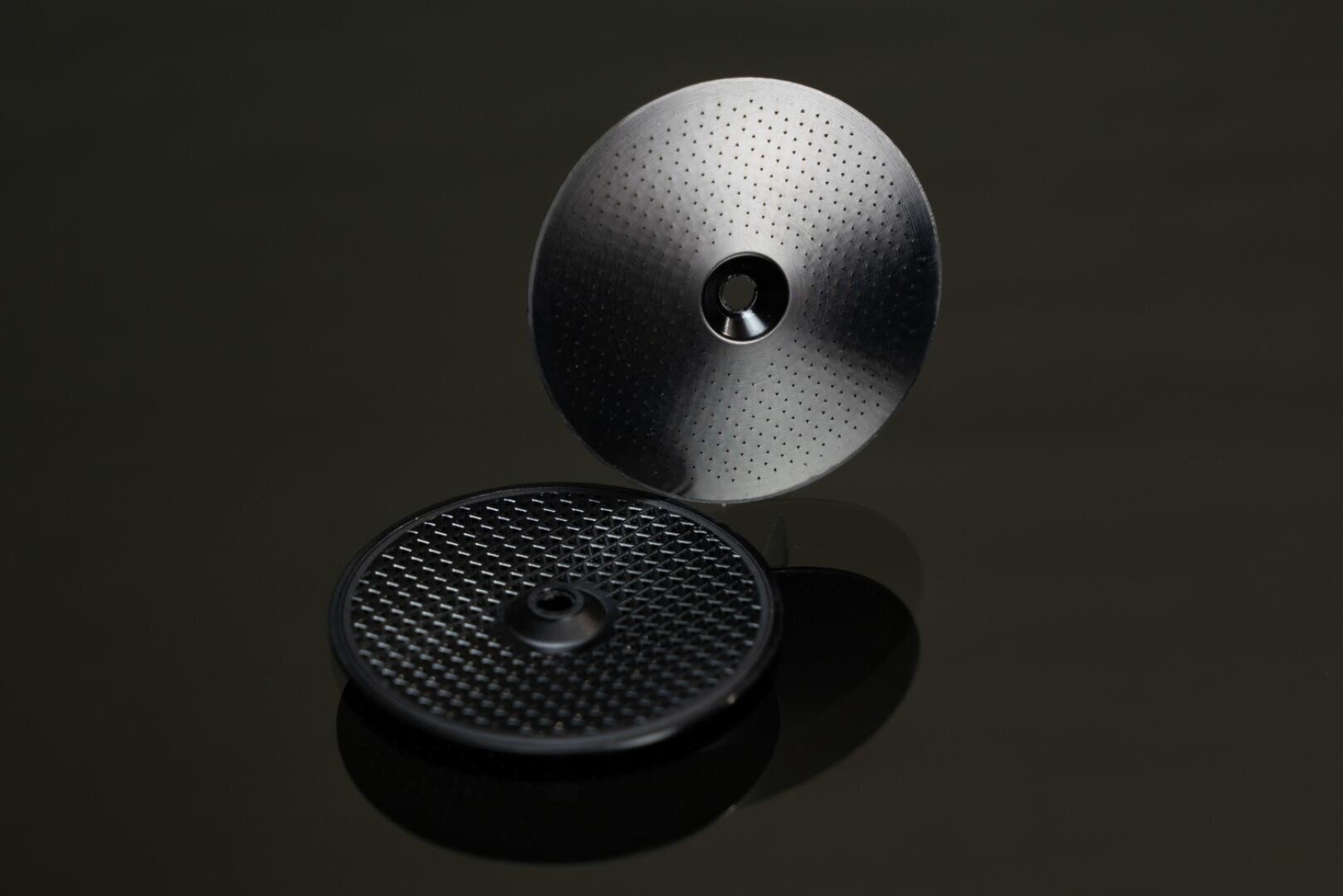

In precision injection moulding, every detail determines the function of a component. Materials react sensitively to temperature, pressure and geometry. To achieve consistent results, tool design, process control and quality control must be perfectly coordinated.

The biggest challenge lies not only in achieving precision, but also in maintaining it consistently in series production.

Our concept

elfo ag develops injection moulding solutions where precision is no coincidence, but rather the result of experience, stable processes and state-of-the-art measurement technology.

We combine toolmaking, process development and series production into a single entity. The goal: reproducible parts that reliably fulfil their function throughout their entire life cycle.

The path to precision

We accompany our customers every step of the way, from the initial idea to the validated series production process. Material selection, tool design, process windows and quality assurance are all interlinked. Every phase is designed for precision – because deviations in the micrometre range can determine the function of an entire system.

The result

The end result is plastic parts that not only ‘fit’ but also function with precision.

👉 Precision plastic parts | elfo ag

For manufacturers, this means consistent series quality, high functional reliability and processes that can be verified at any time.

We are passionate about details – where precision makes the difference and quality becomes visible.

What challenge can we help you tackle?

👉 Get in touch with us: k.berwert@elfo.ch