Mikron Tool Unveils Precision Milling Solutions for CoCr Knee Implant Manufacturing

Cobalt-chrome is tough to cut. Complex geometries push machines to the limit. CrazyMill Knee delivers high-performance milling: optimized cutters, advanced coatings, precise toolpaths, and repeatable results. Faster cycles, longer tool life, superior finishes—machining made reliable. 👉 Read more

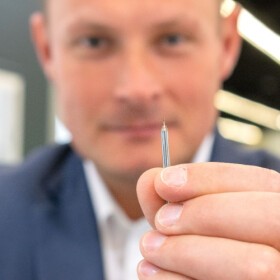

Agno, Switzerland — Mikron Tool is proud to announce the launch of CrazyMill Knee, a groundbreaking range of solid end milling cutters and advanced machining strategies, purpose-built for the precision manufacturing of cobalt-chrome (CoCr) knee implants. This innovative tooling solution is engineered to meet the challenging demands of orthopedic implant production, specifically targeting the femoral component and tibial trays of knee prostheses.

Meeting the Challenge of CoCr Machining

Cobalt-chrome alloys are widely favored in medical implant applications for their exceptional biocompatibility, wear resistance, and mechanical strength. However, their inherent hardness and low thermal conductivity pose significant challenges during machining. Mikron Tool’s new cutter series directly addresses these issues with optimized geometries, advanced coatings, and high-performance substrates that ensure stable, efficient, and repeatable results.

The new tools are designed to deliver:

- Superior surface finishes that reduce the need for post-processing such as polishing

- Extended tool life even under aggressive cutting conditions

- Reduced cycle times through high-speed and high-efficiency milling strategies

- Consistent dimensional accuracy, critical for implant fit and function

Tailored for Femoral and Tibial Components

The femoral component of a knee implant features complex curved condyles and patellar grooves that must mate precisely with the tibial tray and polyethylene liner. Mikron Tool’s cutters are engineered to navigate these intricate geometries with ease, offering:

- Barrel-shaped and ball-nose profiles for smooth contouring

- Micro-milling capabilities for fine details and tight radii

- Optimized flute designs for chip evacuation in deep cavities

These features allow manufacturers to achieve the required anatomical fidelity and surface integrity, ensuring optimal patient outcomes and implant longevity.

Advanced, customized services for orthopedic implant innovation

Orthopedic implant manufacturers get much more than cutting tools— with the CrazyService Products they can benefit from a complete solution:

- CAM-optimized geometries for complex surfaces

- Tool life testing and process validation

- Custom tool development for unique implant designs

- Turnkey solutions and prototyping for tailored, comprehensive solutions

Together, these services and strategies empower manufacturers to streamline production, reduce scrap rates, and maintain the stringent quality standards demanded by the medical industry.

Innovation Backed by Research

The development of this tooling solution is informed by extensive research into the tribological and mechanical behavior of CoCr alloys during machining. Studies have shown that optimized cutter geometries and coatings can significantly improve surface roughness and reduce residual stresses—key factors in implant performance and patient safety.

A Step Forward in Medical Manufacturing

With this launch, Mikron Tool reinforces its commitment to advancing medical manufacturing through precision engineering and innovation. The new range of CrazyMill Knee endmills not only enhances productivity but also supports the global healthcare community in delivering reliable, high-quality orthopedic solutions.

For more information about Mikron Tool’s medical machining solutions, please contact your local representative or visit the company’s website.