Laser plastic welding: consulting, lab tests, small series

Laser welding of plastics, like any joining technique, has its own design rules to achieve good and reliable joints. Additionally to machines, ProByLas also offers support on the design of the plastic parts to weld in order to apply the laser process optimally.

For joining two plastic parts various techniques are possible from mechanical joining (e.g. screws) to adhesive bonding and welding. They all have their specific advantages and disadvantages. And they all have their design rules that should be followed when designing the parts.

For laser welding of plastics, ProByLas offers besides machines also the support in product design for this technique. Initial prototypes can be welded in the application lab and small series production.

Especially if starting a very first design for laser welding without specific experience, such support is very crucial in a development project. The customer gets certainty that the technology works for his parts before investing in a machine.

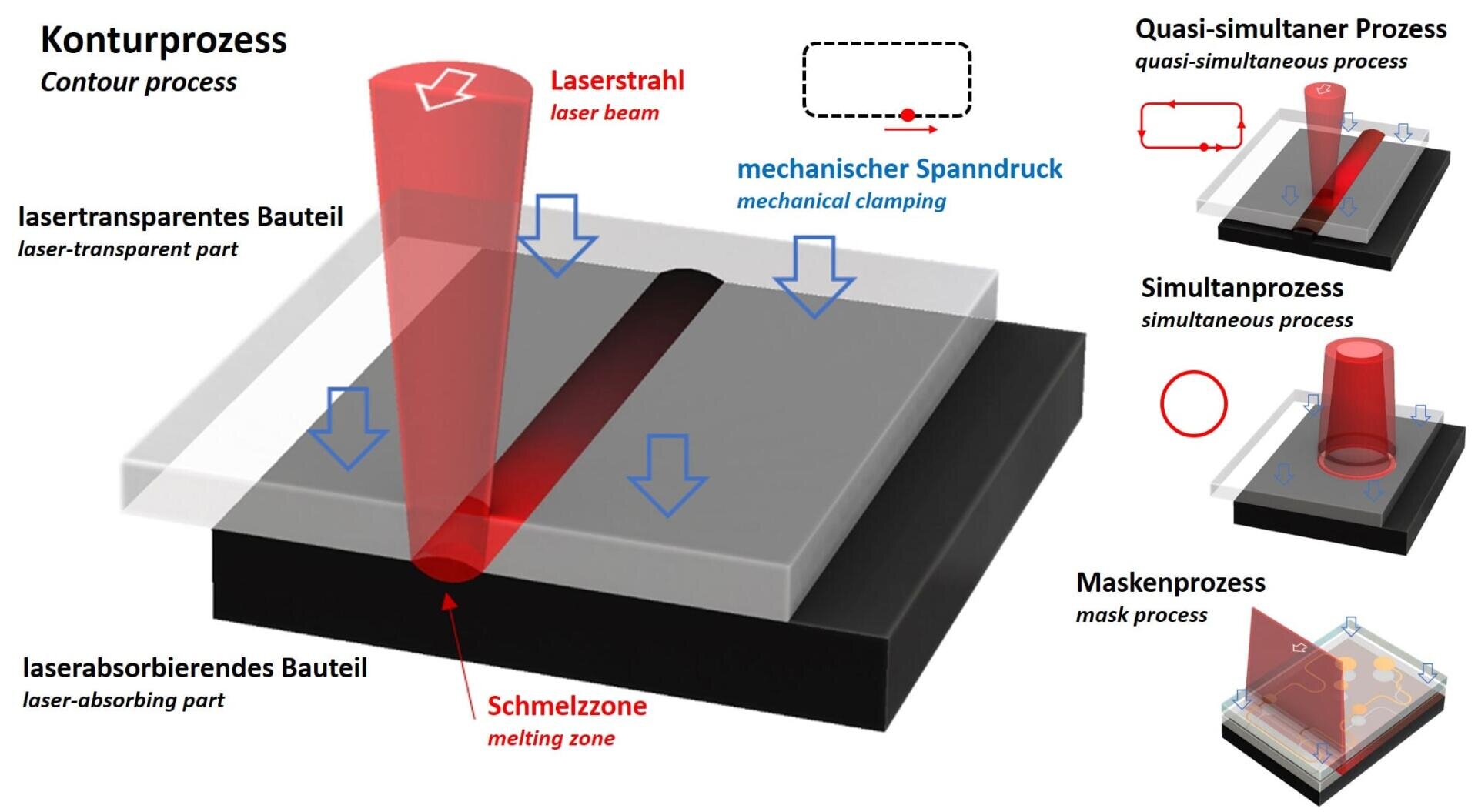

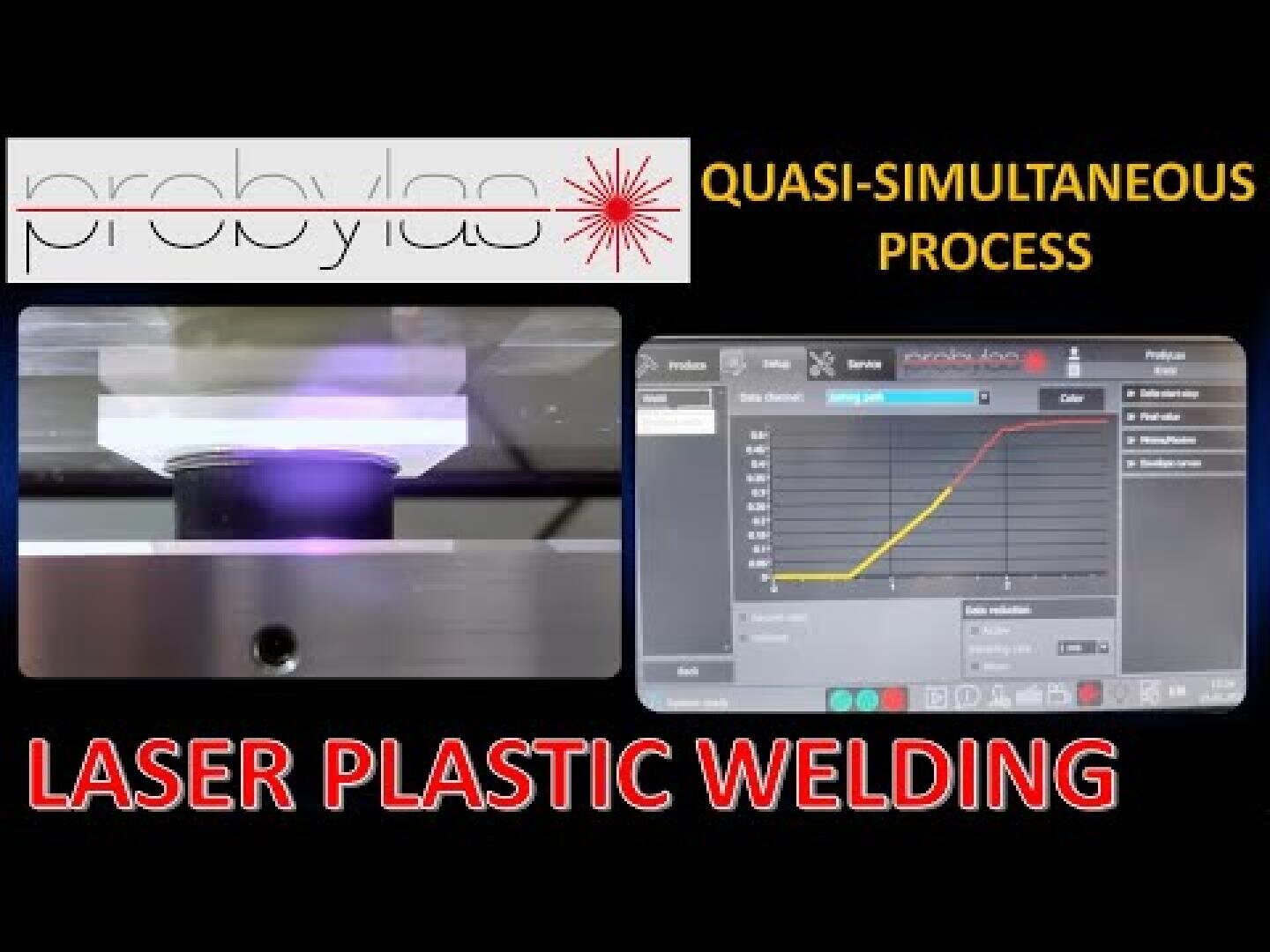

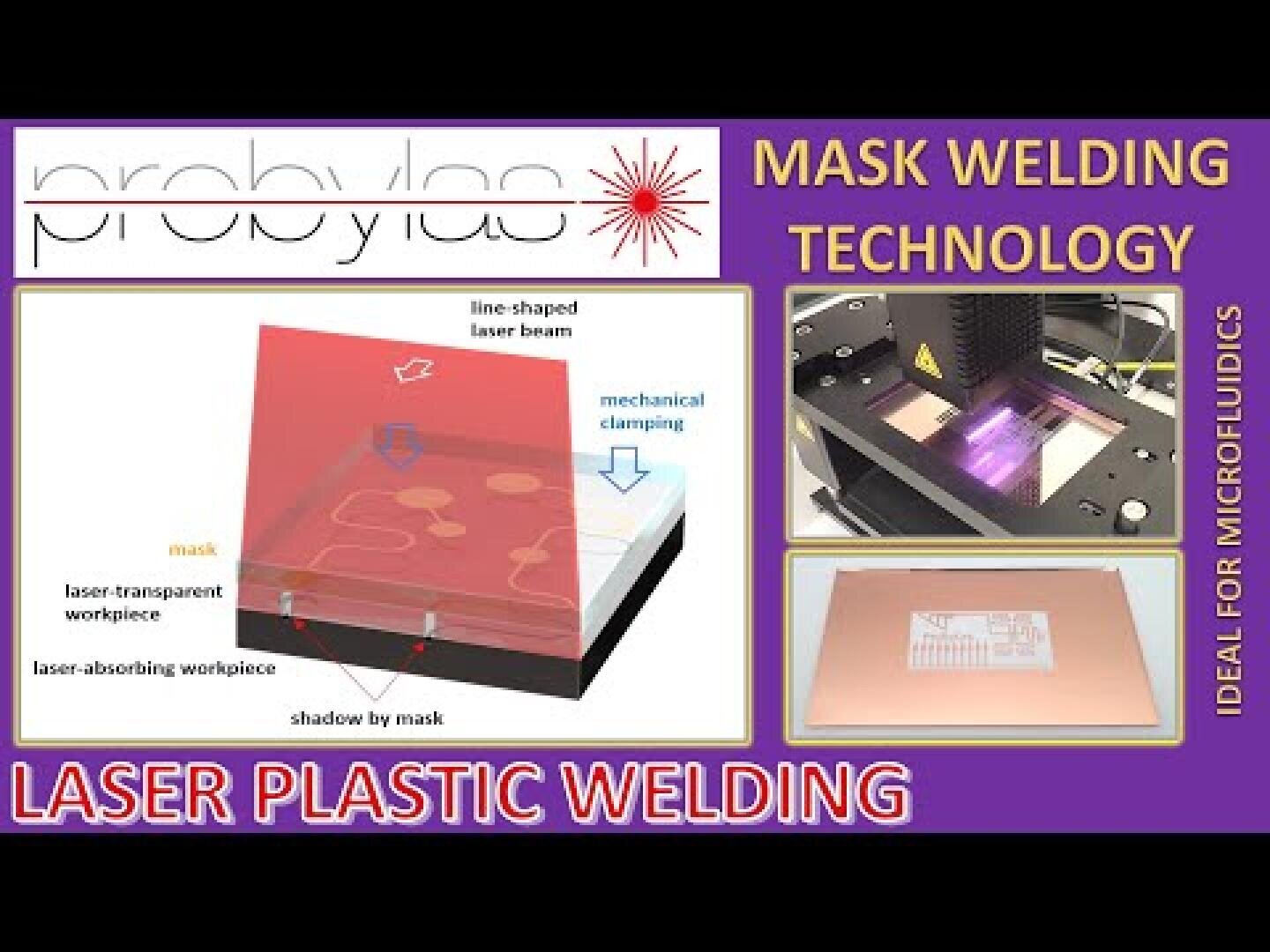

Selection of process type

Different process types (see figure process types) are available for welding plastics. Depending on the parts to weld and the requirements, they are more or less suitable.

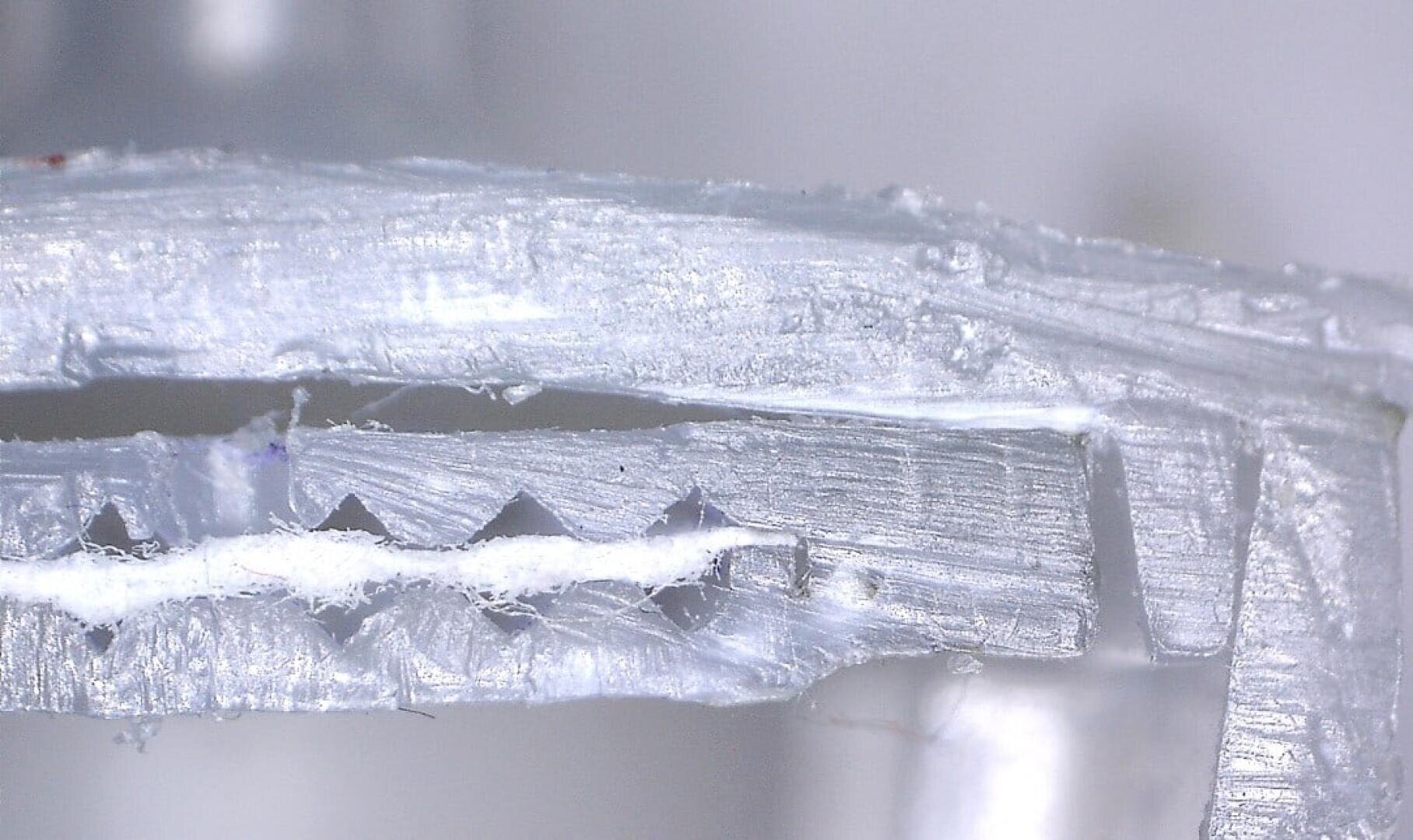

Design of weld seam

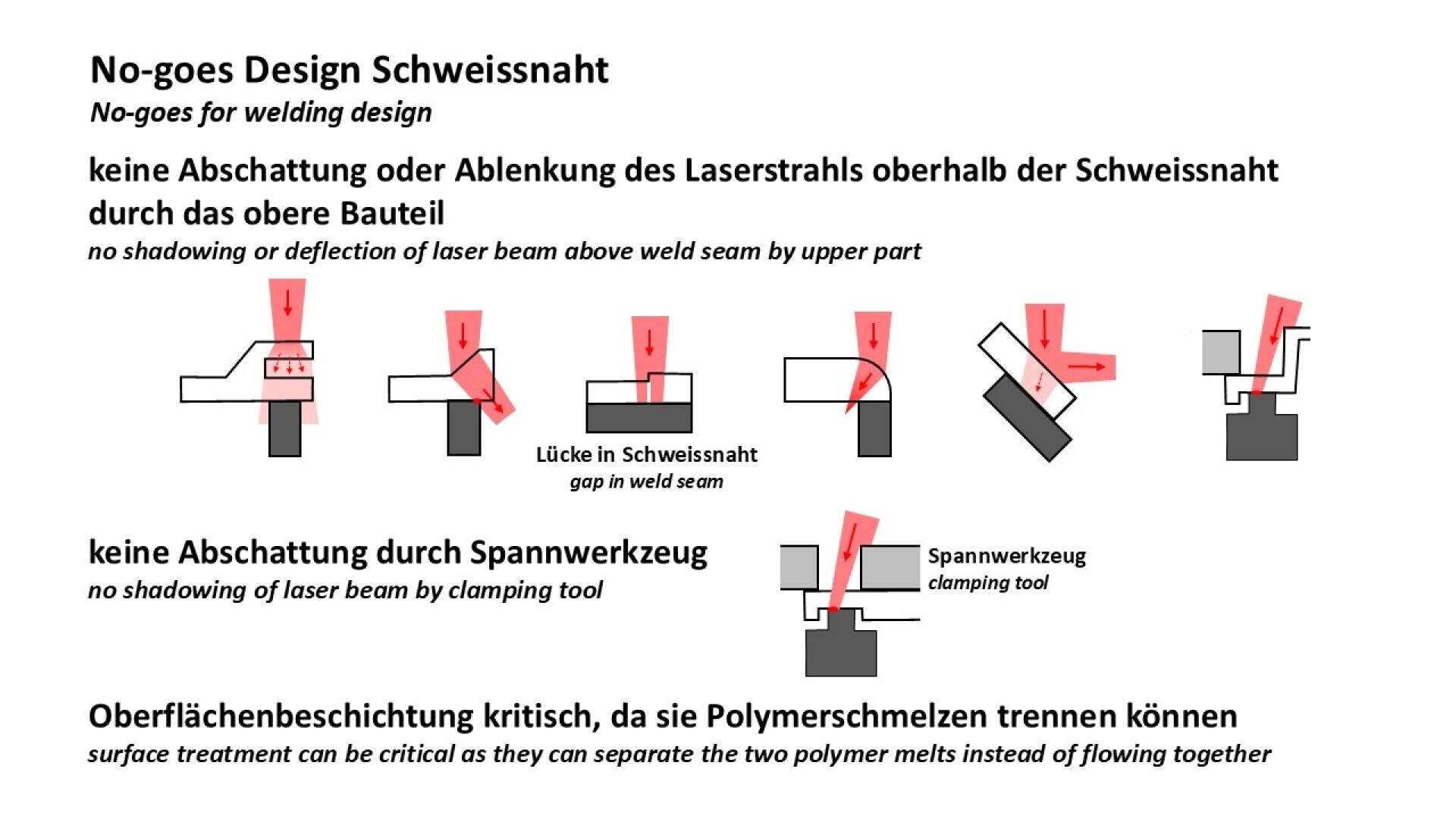

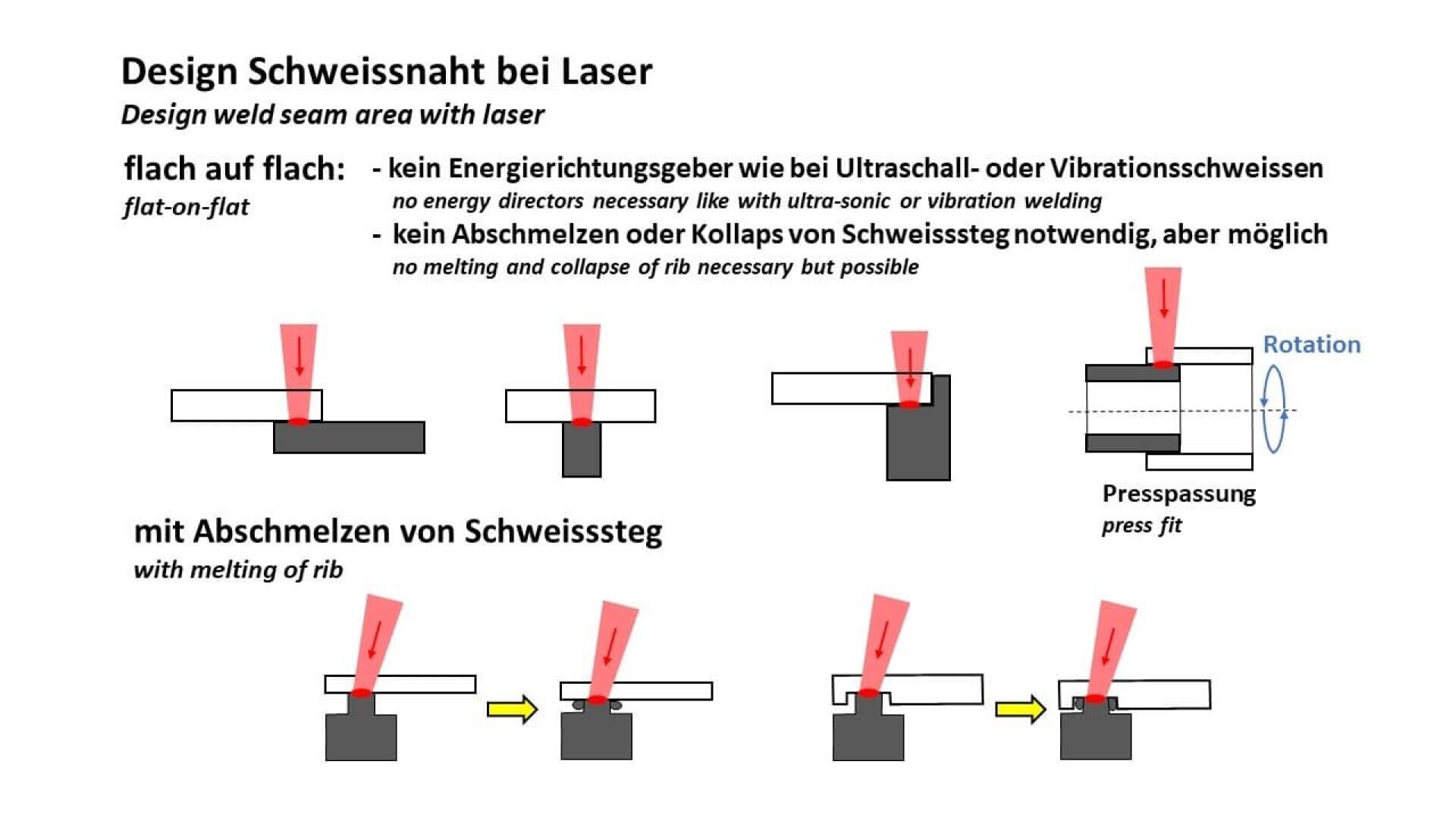

At the weld seam the two plastic parts must lie flat on flat on top of each other. And the upper parts must not deflect the laser beam on its way to the weld seam (see picture design rules and no-goes).

Selection of plastics

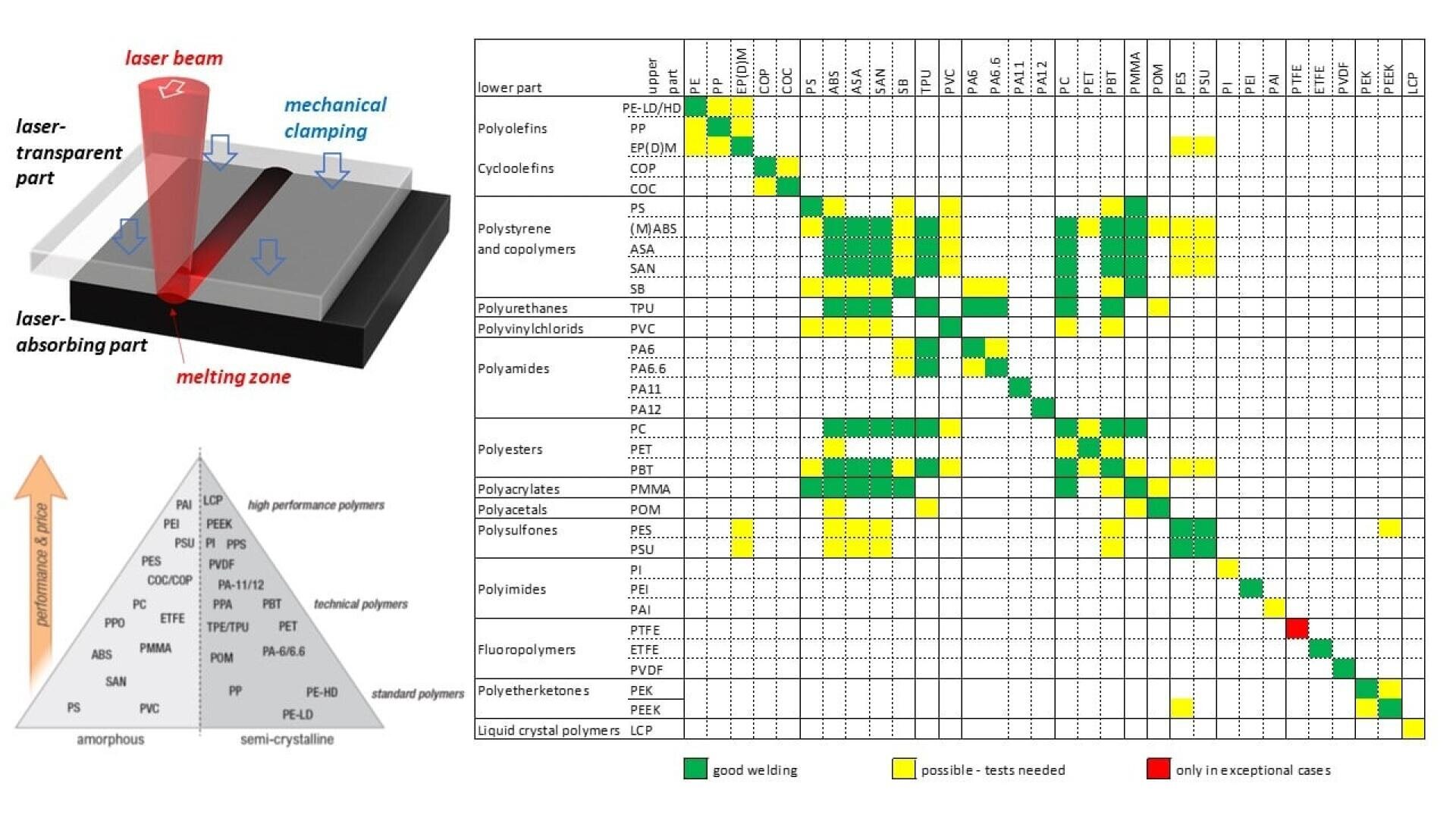

Ideally, the plastics of the two parts is of the same polymer type, so that they can melt at a similar temperature and intermix with one another. In the case of dissimilar polymer types, they should at least be chemically similar enough to mix in the melt (see figure compatibility matrix).

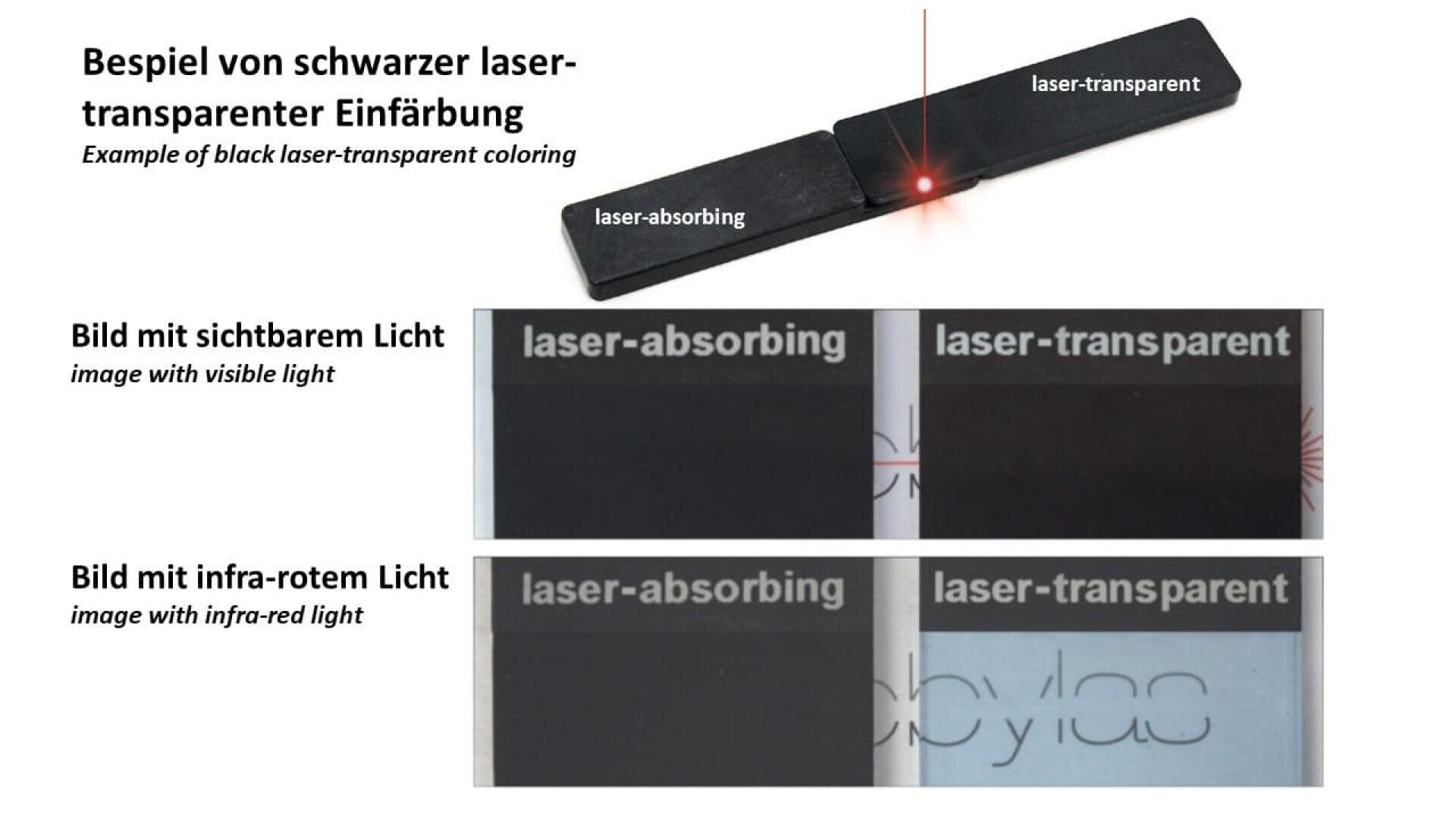

Coloring laser-transparent and laser-absorbing

For converting the energy of the laser beam into heat in the contact area of the two parts, the upper one must be largely transparent to the laser and the lower one must absorb the laser.

Selection of laser type and wavelength

In classic laser welding with a laser-transparent to laser-absorbing part, a fiber-coupled diode laser with a wavelength of 980 nm is usually employed. If the parts require very fine weld seams, a fiber laser (wavelength 1070 nm) is used instead.

If two colorless transparent parts are to be joined without additional colorant, the laser wavelength must be shifted to 1700-2000 nm, at which most polymers slightly absorb the laser light on their own (further details in a separate article on the show platform).

Design of fixture and clamping tool

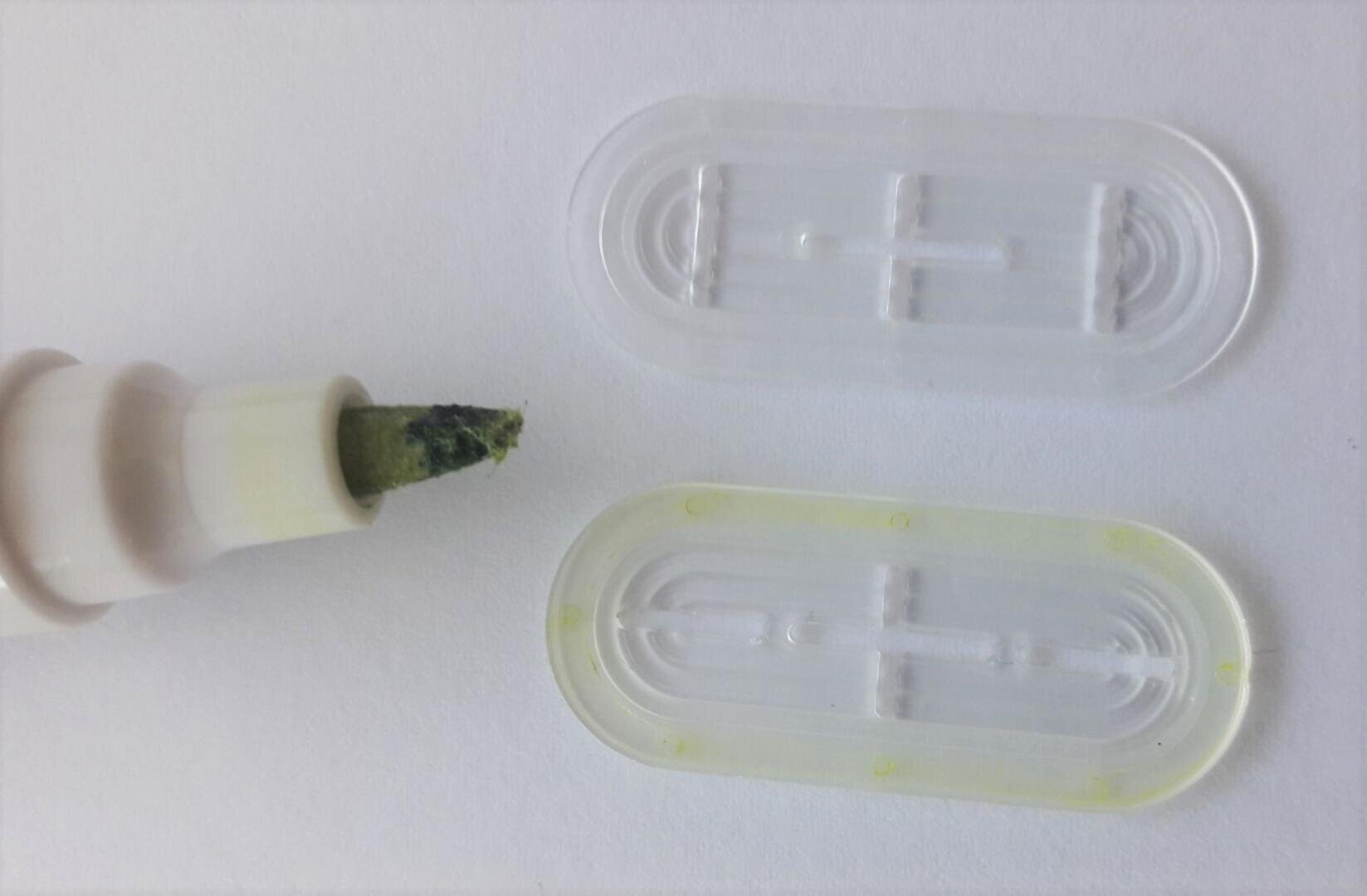

During the welding process, the two parts must be pressed together to ensure heat conduction from the lower to the upper part and to allow the melts to mix. The lower part is aligned with a cavity and supported under the weld seam. A glass plate or a specially adapted clamping tool presses down on the upper part from above and ensures contact with the lower part.

Welding of material samples

If the compatibility of the selected plastics or their coloring needs to be tested first, we can carry out and evaluate initial feasibility tests on material samples in our application laboratory.

Welding of prototype samples

With a design taking well into account above points, prototype parts can be welded in the application lab and the process parameters optimized.

Samples can be tested and analyzed for the desired functionality at ProByLas or at the end customer.

Welding of small series

In the ProByLas application lab smaller series can be welded for more extensive tests at customer or at the beginning of a product launch until an own machine is purchased and available.

Production concept and machine selection

Depending on the targeted quantities, production concept, and requirements on process data for quality monitoring, different process types and machine configurations are best suited.

Rental of machines

For process optimization at customer's premises or for start of production, ProByLas also offers machine rental before the customer invests in his own machine.