Mikron Tool CrazyServices: Engineering Excellence for Complex Machining

Difficult materials, extreme tolerances, zero room for error. When machining gets critical, tools alone aren’t enough. Discover how Mikron Tool’s CrazyServices turn complex challenges into reliable, production-ready processes. 👉 Read more

Agno, Switzerland — In today’s manufacturing landscape, especially where difficult-to-machine materials and precision geometries define competitiveness, engineering support is no longer optional. Mikron Tool’s Crazy Services elevate this support into a comprehensive, end‑to‑end partnership, empowering companies to push technical boundaries without sacrificing time, productivity, or process reliability.

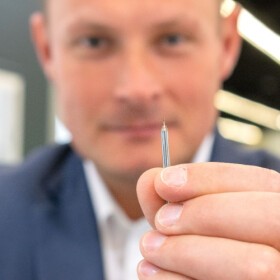

At the heart of this offering is the Mikron Tool Technology Center in Agno, a world‑class facility equipped with state‑of‑the‑art machines and advanced metrology systems. This is an ideal environment for exploring high‑performance machining of demanding materials such as stainless steels, superalloys, titanium, and cobalt‑chromium.

Originally conceived as an internal test laboratory, the Technology Center has evolved into a holistic R&D and engineering hub. Here, Mikron Tool specialists work daily on customer‑specific machining challenges—optimizing processes, validating cutting strategies, and developing turnkey solutions that improve reliability and reduce cost per part. This expertise is now accessible globally through the CrazyService Products, structured service packages designed to meet the unique needs of each project.

A Tiered Approach to Solving Machining Challenges

CrazyServices are built around five core modules, each addressing a critical stage of manufacturing optimization:

1. Tool Evaluation

Manufacturers often lack the machine time and resources to test tooling combinations. Mikron Tool conducts controlled trials to determine the ideal standardized tool for a given application, material, or geometry. Deliverables include detailed measurement protocols, optimized cutting parameters, and documented performance benchmarks—giving customers proven security before investing in new tooling.

2. Process Definition

To optimize a critical machining operation, Mikron Tool reviews drawings or CAD models and develop an improved manufacturing strategy using CrazyTools. The customer receives a comprehensive report including tool recommendations, cutting parameters, CAD/CAM simulations, and a validated machining concept designed to improve cycle time and part quality.

3. Tool Life Testing

To reduce production costs, Mikron Tool performs comparative tool life analyses, identifying the most economical tools for a given process. This includes determining cost per part and revealing savings opportunities through improved tool selection or modified cutting conditions.

4. Process Optimization & Redesign

For complex challenges, the Technology Center team develops an alternative manufacturing strategy that combines newly developed custom tools with tools from the standard portfolio. This service is focused on significantly reducing cycle time, minimizing tool count, and improving final part quality, with all results validated through machining trials

5. Prototype Manufacturing

When customers have a new workpiece concept without a defined manufacturing process, Mikron Tool designs the entire production strategy from scratch. This includes machine selection, cooling solutions, programming, and quality assurance. The project is managed transparently, and prototypes or pilot series can be produced to fully validate the process and eliminate investment risk.

Why CrazyServices Matter

Across industries—from medical technology to aerospace, automotive, and watchmaking—manufacturers face rising pressure to machine increasingly complex materials with perfect repeatability. Mikron Tool’s CrazyServices provide a solution to common challenges: limited internal capacity, lack of specialized expertise, and the high cost of trial‑and‑error testing.

By merging cutting‑edge tools, scientific process design, and hands‑on engineering collaboration, Mikron Tool becomes more than a supplier—it becomes a strategic machining partner dedicated to transforming challenges into reliable production success.

Visit the CrazyService Products website page for further information