Medical laboratory instead of factory floor: how mechanical engineering can open up new markets

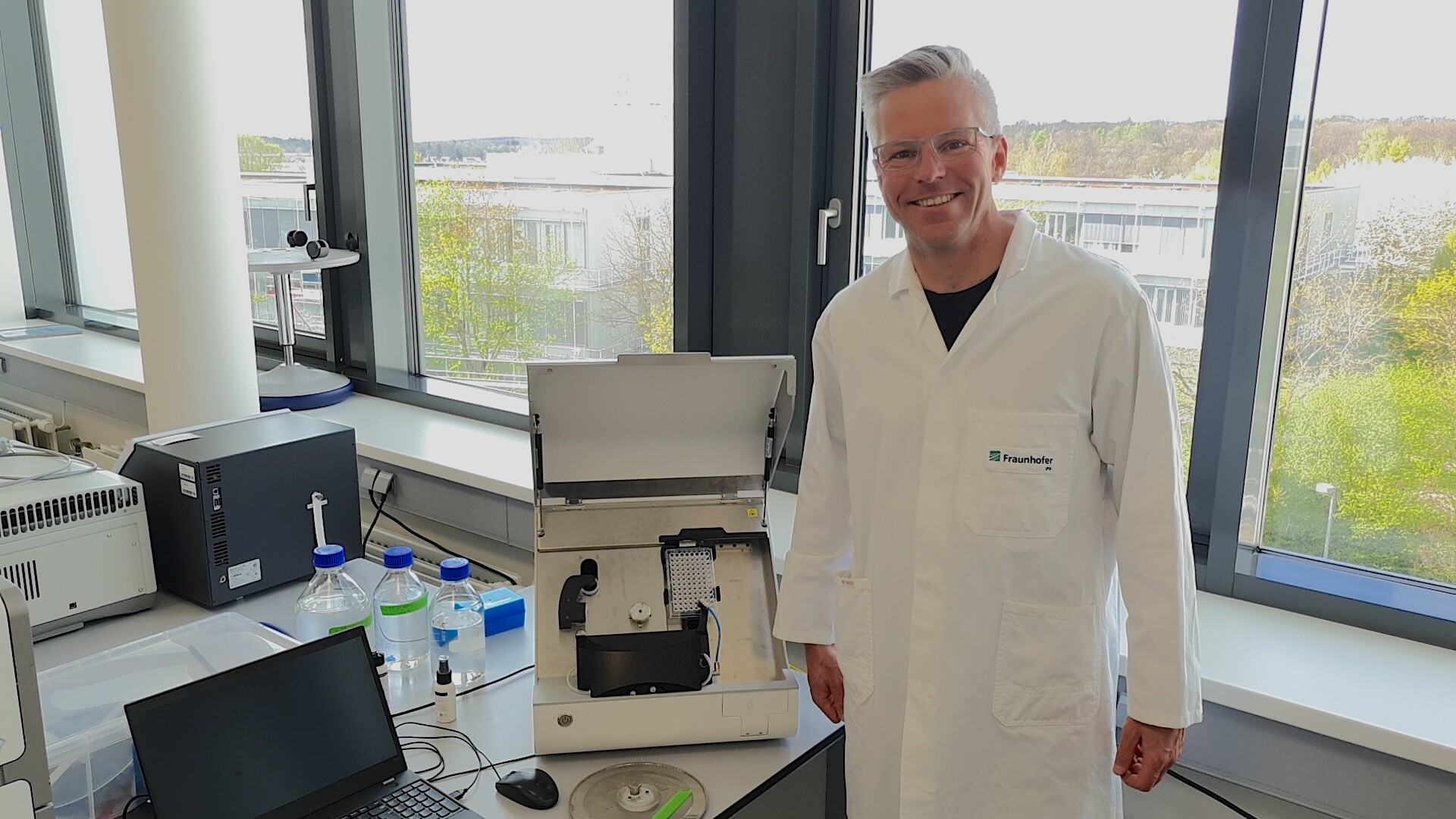

Andreas Traube from Fraunhofer IPA has been researching innovative technologies for laboratories for over 20 years - from precise robot systems to AI-supported diagnostics.

In an interview with MedtecLIVE, he explains why companies from the mechanical engineering sector should consider entering the mechanical engineering sector should consider entering the laboratory technology sector.

Mr Traube, you have 20 years of experience in the field of laboratory automation. What are you currently researching?

Andreas Traube: We are currently focusing on the end-to-end automation of laboratory processes. Many devices still work as stand-alone solutions that are not fully networked with each other. The aim is to develop robotic solutions that can flexibly handle the widely varying sample containers and process requirements - including object recognition, independent task analysis and mobile usability within the laboratory. The reduction of programming effort through AI is also a central topic of our research.

You advise manufacturers of laboratory equipment and laboratories. How does this collaboration work?

Andreas Traube: With end users, we usually start by analysing the existing processes, followed by a profitability assessment and concept development. If successful, we develop customised automation solutions. With manufacturers, the focus is more on fundamental issues such as collaboration capability, object recognition or interaction with other laboratory equipment. In both cases, we see ourselves as the interface between technology and application.

Which technologies that are used in the laboratory today have you developed yourself?

Andreas Traube: One of my first start-ups was the company Dispendix, which developed an extremely fast liquid handling system in the nanolitre range. This system was used during the pandemic, among other things, to carry out large quantities of experiments efficiently. It exemplifies the advantages of automated laboratory systems: miniaturisation, precision and speed.

How is artificial intelligence changing laboratory processes?

Andreas Traube: AI is used in many areas of the laboratory today - for example in image recognition or the interpretation of complex data. In combination with automation, a valuable data pool is created from which prediction models can be derived using machine learning. Generative AI is not yet an option in laboratory diagnostics - the risk of incorrect or fictitious information being generated is too high. That would be a horror scenario. The next steps lie in the broad implementation of classic AI applications for process optimisation.

What progress do you expect to see in robotics over the next few years?

Andreas Traube: Robots are becoming increasingly intelligent and autonomous. Technically, it is already possible today for robots to take on many tasks that were previously reserved for humans - from handling to analysing. Instead of permanently installed stations, robots could be placed on mobile platforms and used as flexible logistics systems within the laboratory. Such mobile systems could, for example, transport samples from one station to the next without human staff having to take care of these routes - a concept that is already being tested in initial pilot projects. I also expect decisive progress to be made in terms of intuitive operability so that laboratory staff can work efficiently with robots without any programming knowledge.

Why should industrial companies from other sectors consider entering the field of laboratory automation?

Andreas Traube: Laboratory automation is an area with enormous potential that is often underestimated by traditional industry. Companies that have previously focussed on automation in areas such as automotive production could open up new areas of business here. We see time and again that companies that take the plunge into medical technology benefit from it in the long term - and so far none have regretted it. Of course, it is a challenge to enter a regulated industry, but as a Fraunhofer Institute we support such processes and help to develop technological solutions for laboratories. For German mechanical engineering in particular, laboratory automation could be a key area for remaining competitive in the future.

Can automated processes in laboratories promote the trend towards individualised medicine?

Andreas Traube: Definitely. The precision and reproducibility of automated processes form the basis for meaningful diagnostic data - and therefore for personalised therapeutic approaches. By combining automation and intelligent data analysis, laboratory processes can not only be made more efficient, but also more stable and meaningful.

How do you assess the openness of laboratories and medical staff towards new automation technologies

Andreas Traube: That varies greatly. I know laboratories that can no longer imagine operating without automation - and others that are still hesitant, for example for budgetary reasons or due to a lack of technical expertise. Hospital laboratories in particular are often more reluctant to automate, mainly due to costs and the trend towards centralising diagnostic services. In general, however, it can be said that laboratories that invested in automation at an early stage now work more efficiently and are often more successful.

What does the ideal laboratory of the future look like for you?

Andreas Traube: An ideal laboratory is an environment in which samples are processed quickly and without errors - regardless of whether processes are manual or automated. The aim is to reliably translate physical samples into diagnostically relevant information. Humans and machines work hand in hand here: robots and AI provide support as tools, but the responsibility for the diagnostic statement remains with the human - and this will also remain the case from a regulatory perspective.

Thank you very much for the interview!

About the person

Andreas Traube is head of the business unit health industries at the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA). He studied mechanical engineering and has been involved in the automation of laboratory processes for over 20 years. His focus is on applied research aimed at transferring innovative technologies into practice. In addition to his work at Fraunhofer IPA, he has founded several companies in the field of laboratory technology and has co-founded companies specialising in automated dosing systems and laboratory equipment.

Customised formats for the medical technology sector

MedtecLIVE is the leading trade fair in Europe for the development and manufacture of medical technology. It is part of a Brand Family that offers the industry more than just a trade fair and supports it in advancing medical technology with its wide range of products and services as well as its strong network and partners. This creates several platforms at Stuttgart, Nuremberg and Munich, where the most diverse players in the industry can meet their target group in a customised way.