LASER JOB SHOP FOR MEDICAL PRECISION PRODUCTS

We produce your precision components! Contract manufacturing with state-of-the-art laser technology is one of the main businesses of LLT Applikation. Whether prototypes, single units or large series, we provide the equipment and the know-how to manufacture your components in quality and on time.

More than 25 precision machines with a wide range of laser sources are available for processing your production orders. In addition to conventional Nd:YAG lasers and robust fiber lasers, ultra-short pulse lasers are used for the precise processing of sensitive materials. Highly qualified employees and certified quality management make sure that your product meets the very highest requirements - your requirements.

| Brochure "Laser Job Shop" [PDF] |

We produce your 2D and 3D precision components. In addition to conventional flat components, our contract manufacturing also processes complex 3D products for a wide range of industries. Thanks to different laser technologies and components, the scope of materials to be processed is wide and allows highly complex contours with kerfs of up to 10 micrometers. We mainly process foils and thin sheets with material thicknesses from 5 µm to 3 mm. Depending on the specific material and component dimensions, the limits can be extended.

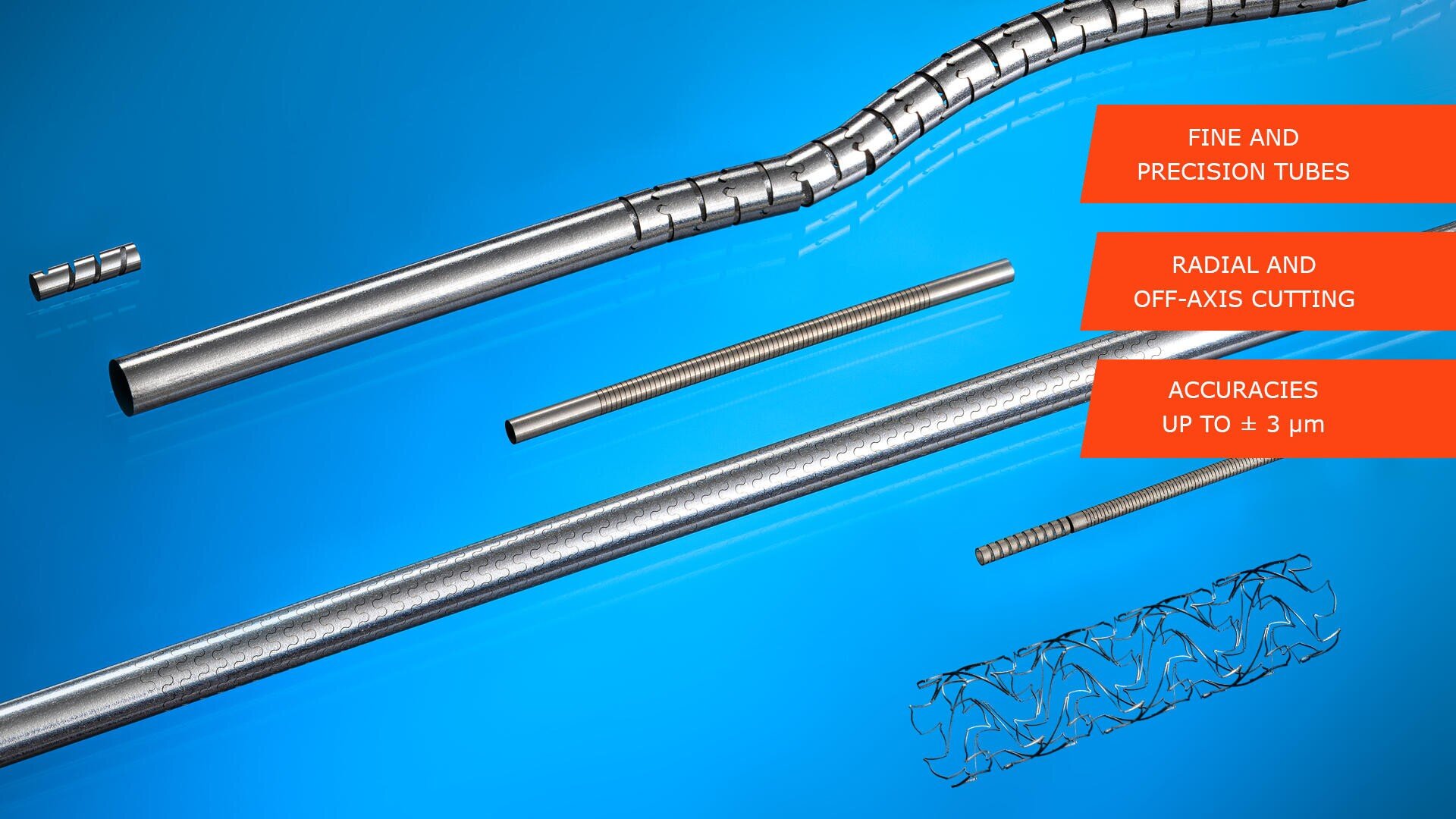

We produce your fine and precision tubes. These components are used in a number of high-tech industries. Especially in medical technology they have an important meaning. Whether a simple cut or the production of complex contours with very small dimensions, the combination of exceptional quality requirements and materials requires special expertise and equipment to manufacture and process these products with lasers.

We finish your precision parts. Even with high-precision laser machining, post-treatment of processed components may be necessary to get a perfect finish. We do this final step for you. You save time and money and there is no need to find an additional service provider.