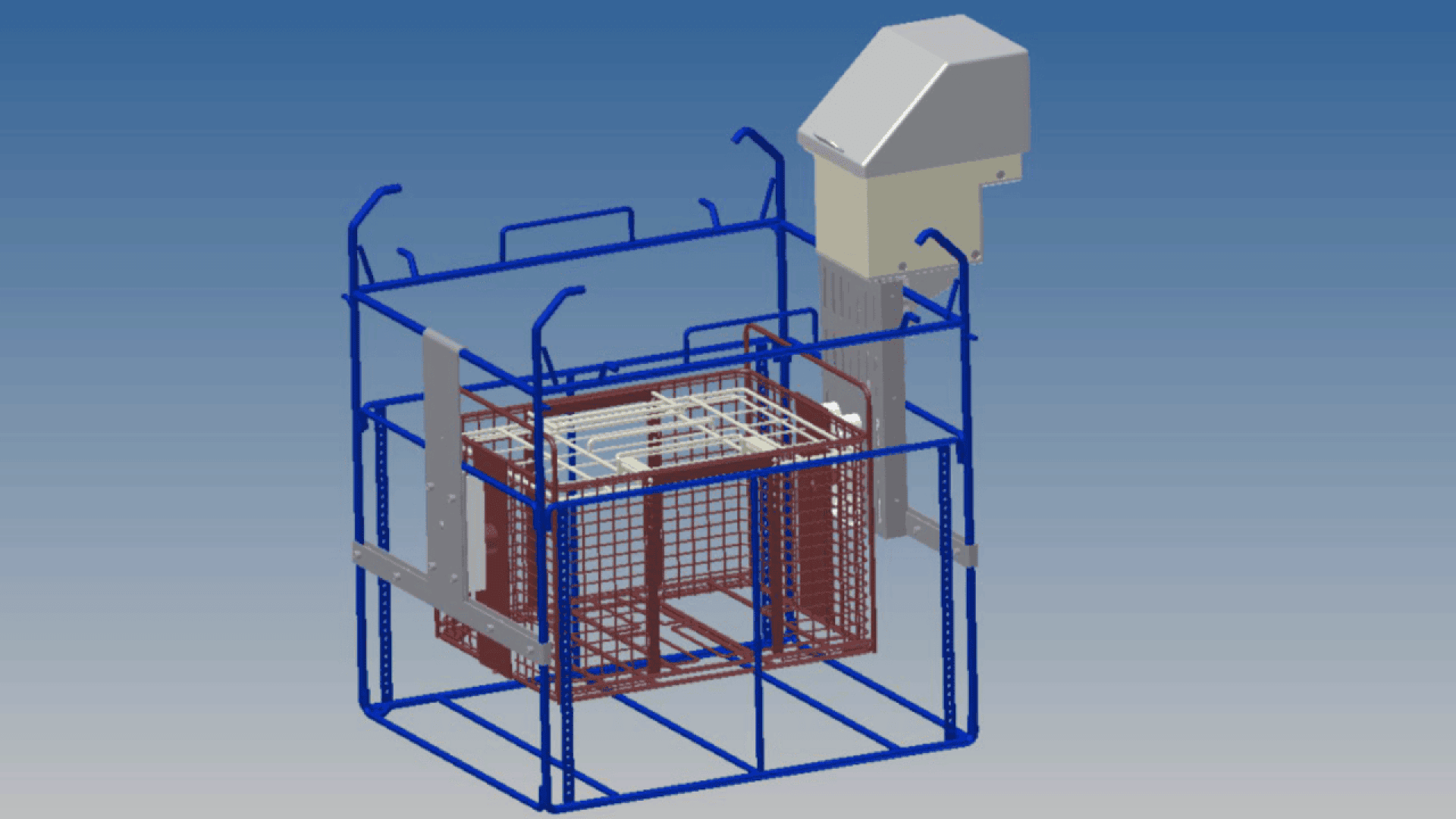

Intelligent cleaning basket

A modular rotation system was developed for ultrasonic cleaning systems, which can be used on existing systems without the need for costly modifications. This was achieved by integrating the control system and power supply via a battery system.

A modular rotation system was developed for ultrasonic cleaning systems, which can be used on existing systems without the need for costly modifications. This was achieved by integrating the control system and power supply via a battery system.

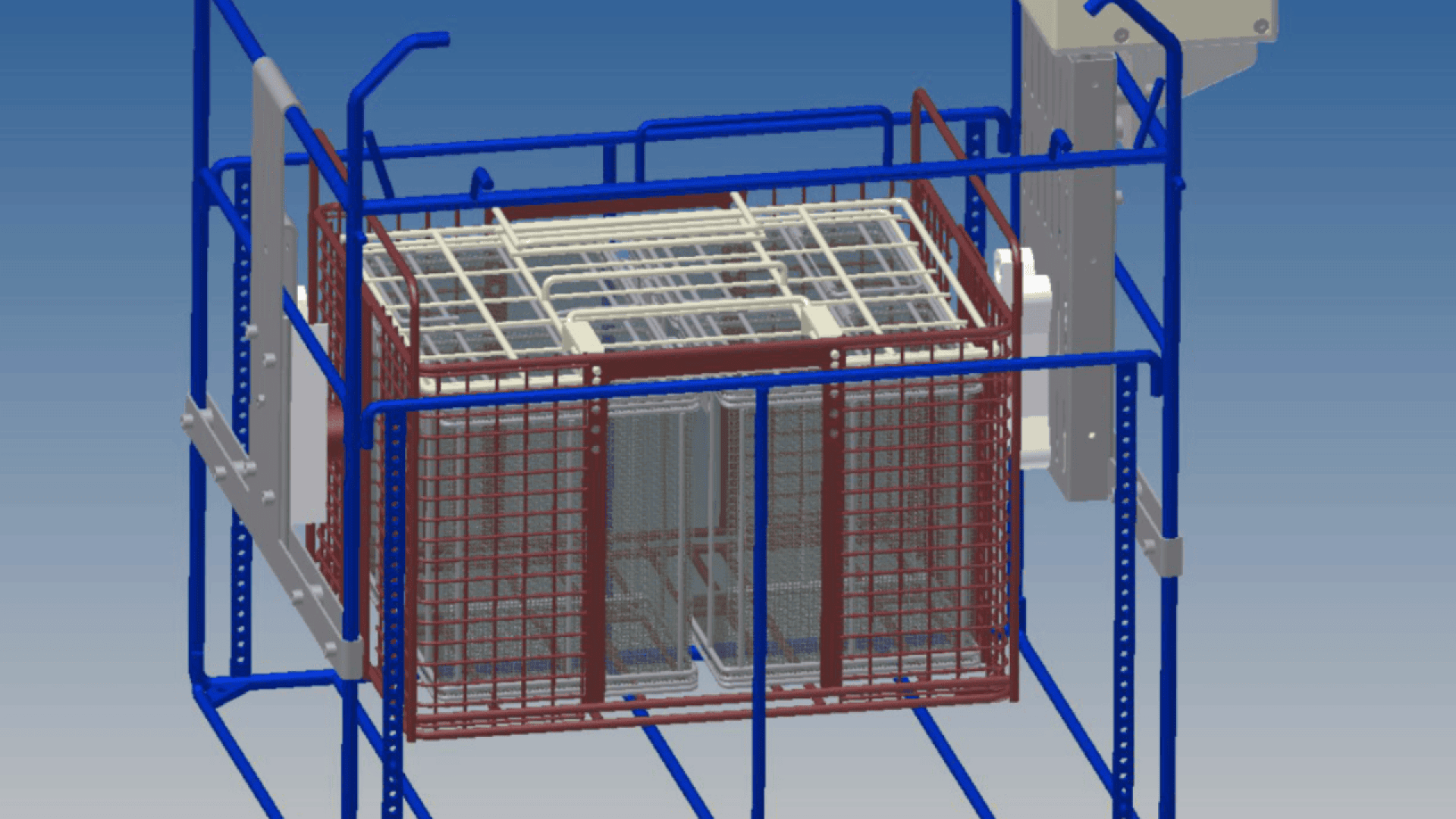

The rotation basket from Bo-Inno can be repeatedly adapted to a changing cleaning task by adjusting the programs. The following parameters can be entered:

- Basic parameters: Number of revolutions, direction of rotation, speed, zero point position when leaving the cleaning medium, start of rotation when immersed in the cleaning medium

- Rotation mode

- Alternating rotation mode with number of rotations per direction

- Swivel with the number of swivels and the angle of the swivel in each direction

- Manual operation in which each position can be approached by hand

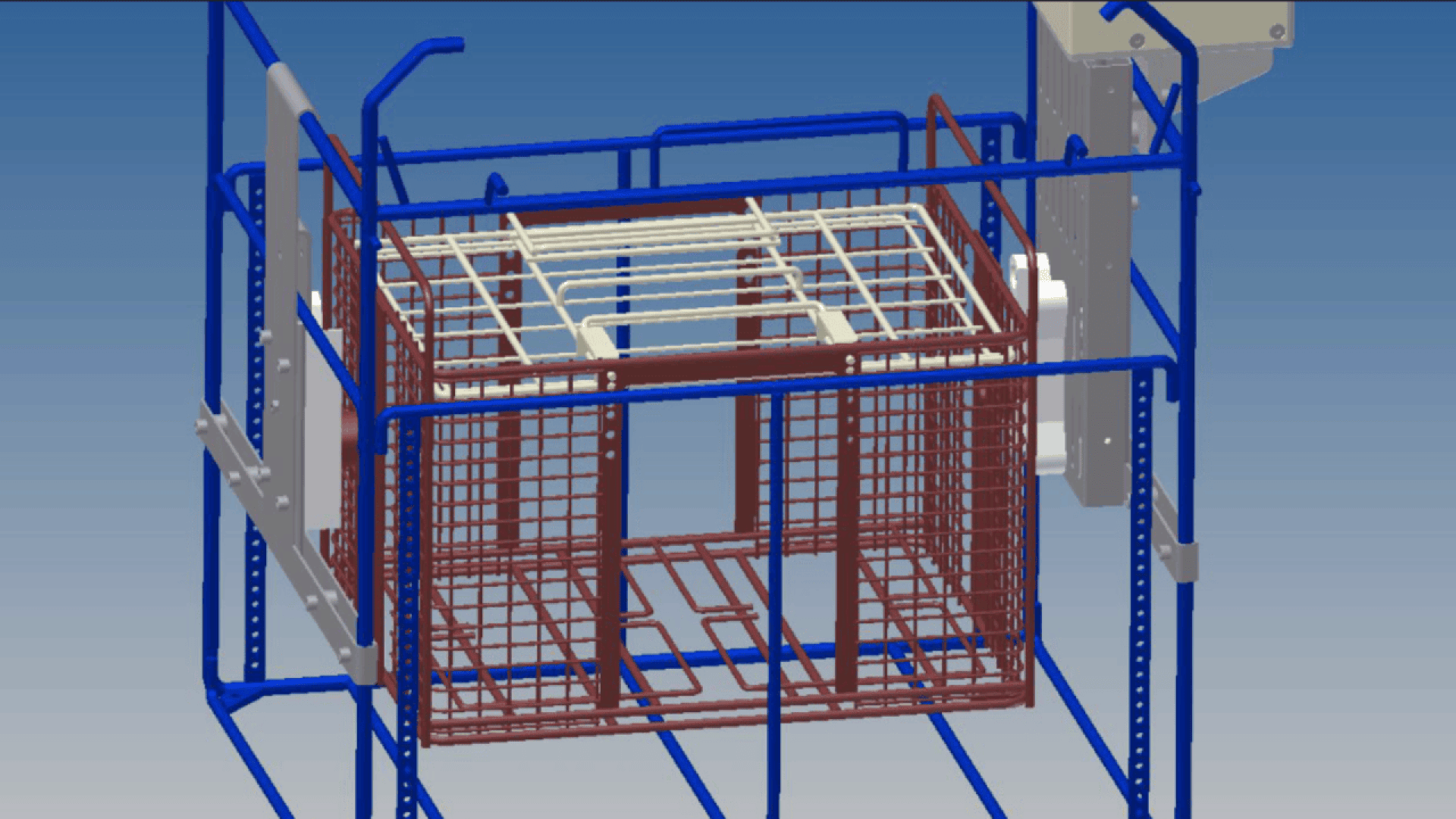

If the components are to be cleaned in several stages, a separate program can be written for each stage. This allows the component to be given the optimum programming within the cleaning basket. The individual cleaning sequence for this carrier is only started when the system is introduced into the process. This is the ideal solution, especially for a wide variety of components, in order to run the most cost-effective and energy-optimized process in terms of cleaning time and drying time.