How Accumold is redifining micro molding for the next era of innvoation

Accumold’s 130k‑sq‑ft, EF5 Tornado resistant facility sets the standard when it comes to micro‑molding. With 150+ presses, in‑house tooling, metrology, and 24/7 operations, it scales ‘impossible’ parts for medical, electronics, optics & emerging tech - reshaping what precision manufacturing can do.

In an age where innovation is defined by how small (and precise) manufacturers can go, few companies exemplify mastery of the microscopic better than Accumold. From its 130,000 square foot facility in Ankeny, Iowa, Accumold is not merely making parts, it’s reshaping expectations across medical, electronics, micro-optics, and emerging technology sectors. By fusing deep engineering expertise with vertical integration and relentless innovation, Accumold has become the gold standard for high-precision micro molding at scale.

Though its facility is capable of withstanding extreme natural events, such as EF5 tornadoes, the real story lies not in the architecture of the building, but in the architecture of the process inside. Accumold’s commitment to repeatable, reliable, and cost-effective production of intricate components is what makes it indispensable to companies seeking solutions at the limits of modern manufacturing.

THE STRATEGIC ROLE OF MICRO MOLDING IN ADVANCED MANUFACTURING

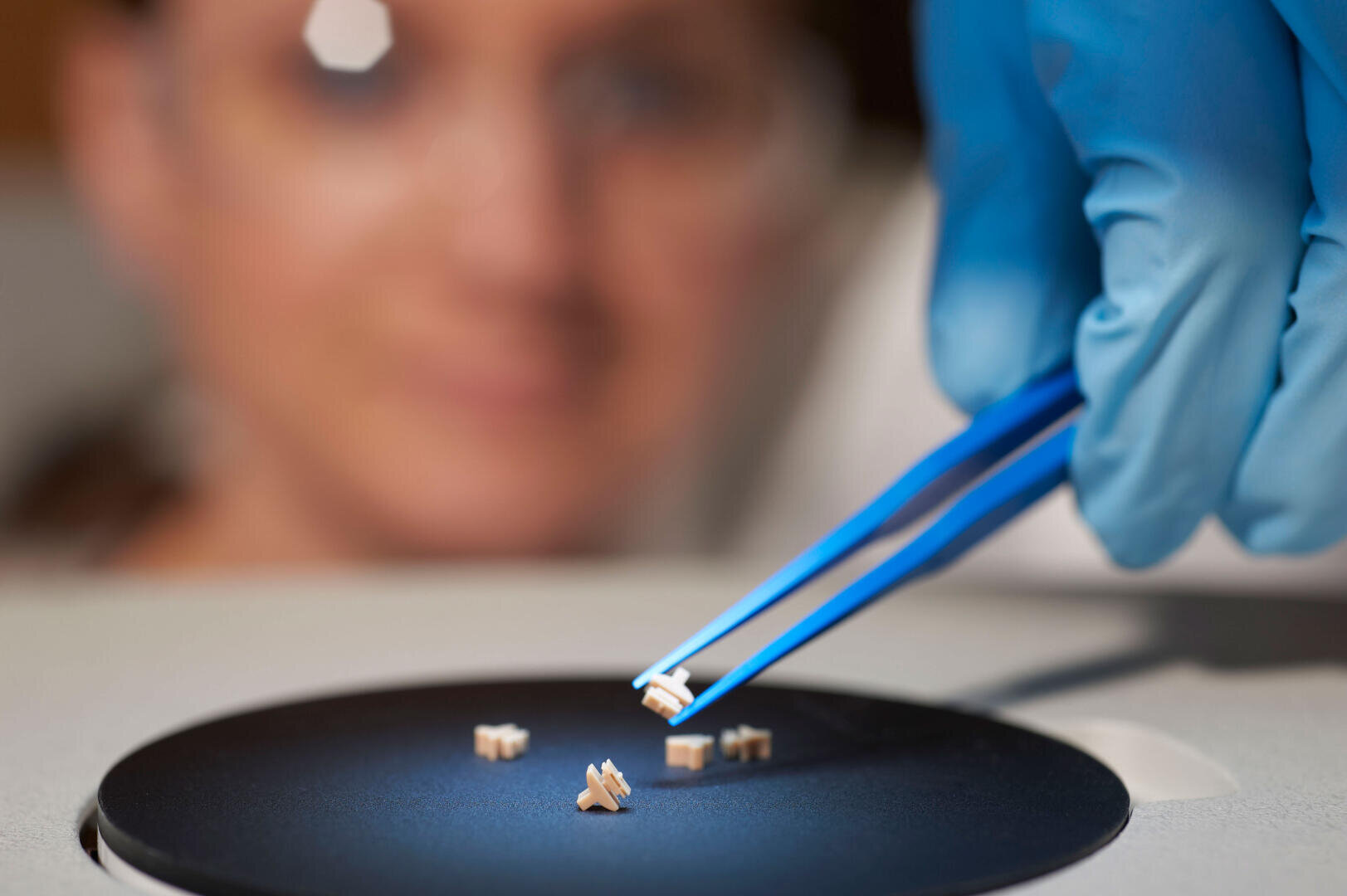

At its core, micro molding is more than shrinking parts. It is about achieving exact tolerances, replicating intricate geometries, and maintaining stability across millions (sometimes billions) of parts. In this domain, conventional molding rules no longer apply. The shift to micro demands a fundamental change in mindset, engineering approach, and organizational structure.

Accumold didn’t just adapt to this complexity, it built a business around it. Since its founding in 1985 with the invention of the first Micro-Mold® press, the company has evolved to a critical innovation partner for some of the world’s most demanding OEMs. Today, it runs 24/7 operations with over 150 molding presses, and a staff of 350+, manufacturing for a global client base.

What sets Accumold apart is not just its ability to manufacture at micro scale, but to do so reliably, efficiently, and repeatedly, all while maintaining tolerances in the single-digit micron range.

VERTICAL INTEGRATION: MASTERY AT EVERY STAGE

While many suppliers focus on discrete stages of the manufacturing process, Accumold has opted for total control. This means owning every critical step, from design for micro molding (DfMM) and in-house tooling to production, metrology, and even micro-scale automated assembly. This approach allows the company to minimize risk, reduce delays, and optimize for cost, quality, and performance simultaneously.

Early collaboration is key. Accumold engages with customer engineering teams at the conceptual stage, helping refine designs before they become costly to modify.

By involving specialists from tooling, molding, and assembly teams from the outset, Accumold ensures that every design is not only theoretically manufacturable, but also practically scalable.

SOLVING THE "IMPOSSIBLE"

Accumold is frequently called upon to manufacture parts that others have deemed impossible. Whether it’s wall thicknesses of just four-thousandths of an inch or micro-optic components with invisible details, the company repeatedly delivers where others fall short.

This relentless pursuit of solutions also extends to pushing industry boundaries. In a landmark thin-wall molding study, Accumold achieved aspect ratios as high as 42:1 using mainstream materials like polypropylene and LCP, vastly exceeding industry expectations. These findings, now in their fifth generation of application, have unlocked new possibilities in areas like medical micro-cannulas and minimally invasive surgical components.

MEASUREMENT AS A COMPETITIVE ADVANTAGE

As any precision engineer knows, if you can’t measure it, you can’t make it. That’s why metrology is not an afterthought at Accumold, it’s an integral part of the development process.

As parts get smaller, tolerances do too. Metrology systems are required that match the scale of what is being produced. This includes white light interferometry systems enabling sub-nanometer measurement of features. Accumold also employs multi-sensor vision systems, pattern-recognition inspection tools, and custom-built fixtures for micron-level repeatability.

This metrology-first philosophy ensures that validation and process control are embedded from design through production, a must-have in regulated sectors like medical devices and telecommunications.

BUILT TO SCALE WITH CONFIDENCE

Micro molding is difficult, but it’s even more difficult at volume. Many companies can prototype a small part; few can scale to millions without compromising on quality or delivery. This is where Accumold’s investment in automation and operational scale comes to the fore.

With dedicated molding cells for high-volume production and fully integrated automation solutions designed in-house, the company delivers cost-effective scalability with consistent results. Their proprietary ERP system adds another layer of traceability, logging every material lot and production step.

In an industry where many vendors struggle to maintain capacity through market shifts, Accumold’s long-term investments and consistent growth give customers the assurance they need to commit to extended programs.

EDUCATION AND TALENT DEVELOPMENT

A factory is only as strong as its people. Aware of the skills gap in toolmaking and micro manufacturing, Accumold partnered with Des Moines Area Community College (DMACC) to create a scholarship program. Students receive a full scholarship, hands-on experience during training, and guaranteed employment upon graduation.

This program has helped replenish the pipeline of talent that underpins Accumold’s in-house tooling expertise, arguably the heart of any micro molding operation. The company now supports up to ten students annually, ensuring future growth is rooted in both expertise and continuity.

PRECISION THAT TRANSFORMS INDUSTRIES

More than 60% of Accumold’s output serves the medical sector. Applications include neurostimulators, pacemaker leads, microfluidic cartridges, and advanced diagnostics.

Outside healthcare, Accumold is a go-to partner for microelectronics and optics. Recent projects have included micro lenses for phones, wearable sensor housings, and other advance technologies.

Accumold’s latest R&D focus is on Additive Manufacturing to further compress development timelines. These capabilities could deliver functional parts in under a week, dramatically accelerating time to market in a competitive landscape.

SUMMARY

Accumold’s story is more than micro parts, it’s about setting a new standard in precision manufacturing. The company has carved out a position not by following industry norms, but by challenging them.

By aligning engineering excellence with strategic foresight, Accumold delivers more than components. It delivers capability, scalability, and sustainability in a manufacturing world defined by complexity and speed.

Editorial notice:

This article is based on the corresponding presentation during MedtecLIVE Innovation Expo 2025.

Meet Accumold at MedtecLIVE Healthtech Pavilion at automatica 2025 in Munich (24 - 27 June 2025) and get your free day-ticket now.