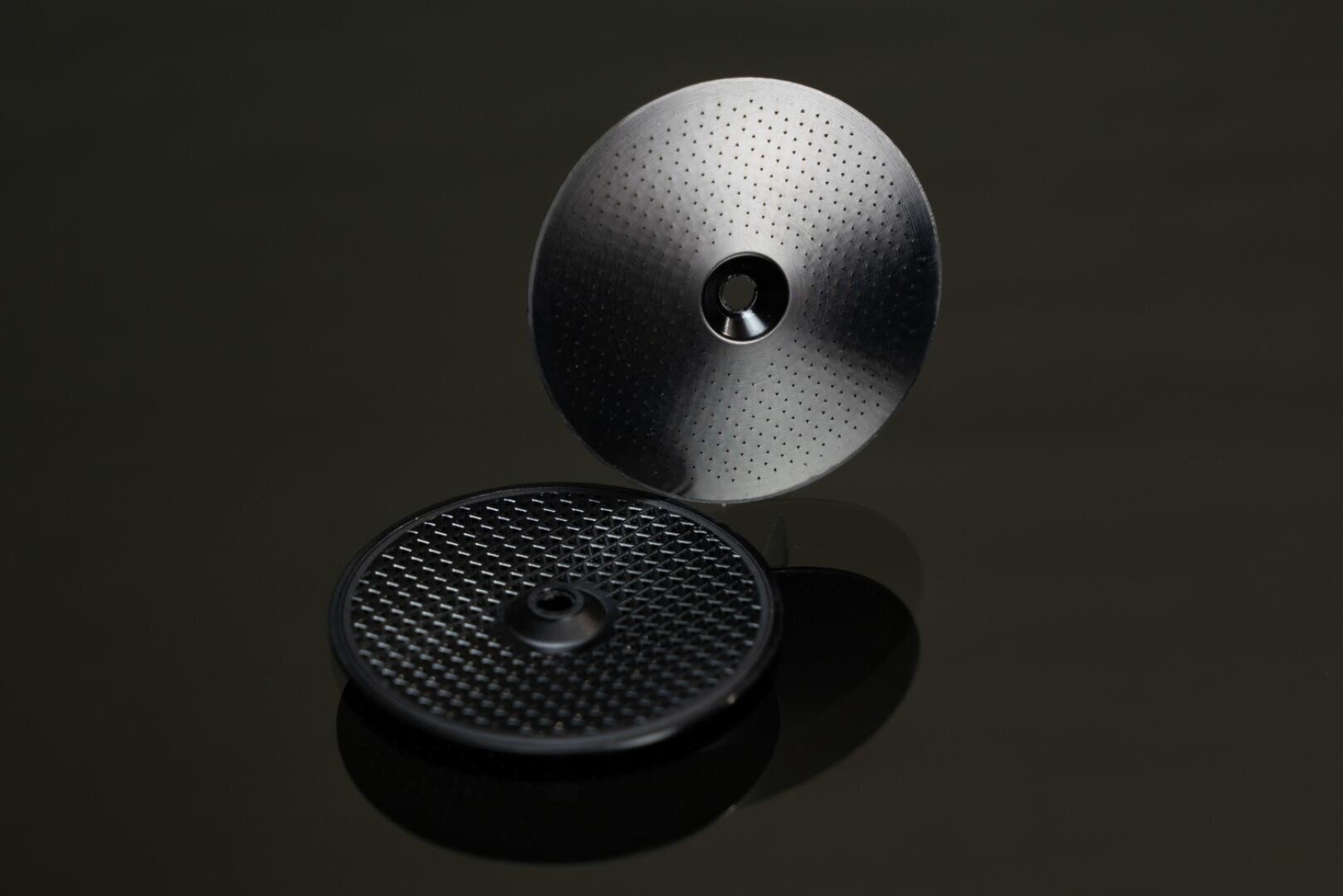

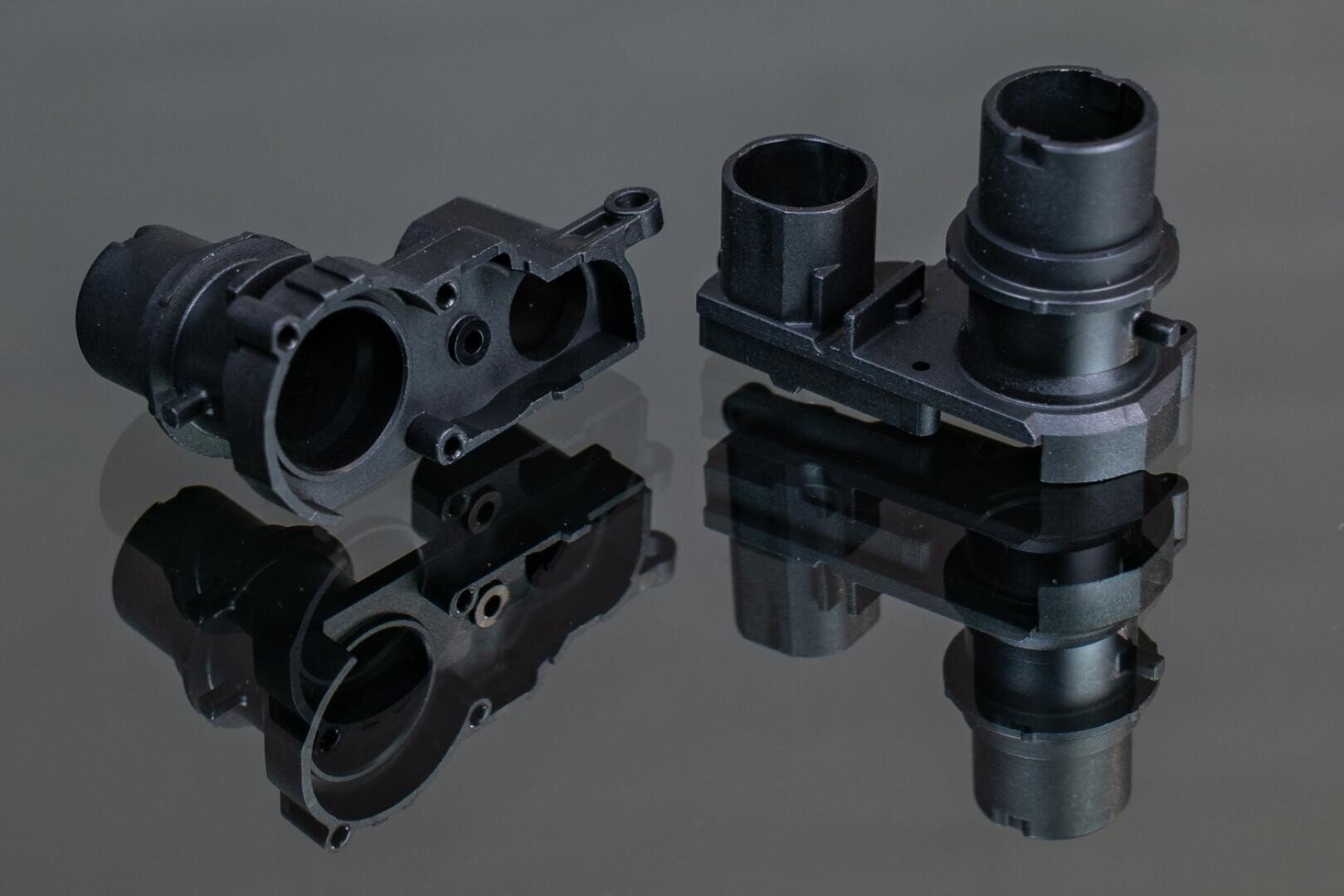

High-performance plastic parts – when standard is not enough

High-performance plastics make it possible to replace metal components with lighter and functionally optimised plastic parts. This offers advantages in terms of durability, part weight, design freedom and cost-effectiveness in series production.

High-performance plastic parts are used wherever components have to withstand high thermal, chemical or mechanical stresses. In medical technology, this applies in particular to components used in analysis devices, laboratory automation or reusable systems. At elfo ag, we manufacture customised parts using plastic injection moulding processes.

High-performance plastic parts | elfo ag

Properties and advantages of high-performance plastics

High-performance plastics are a class of materials characterized by exceptional thermal, chemical and mechanical stability. They can be used in environments where standard or engineering plastics reach their limits.

For applications in medical technology, high dimensional stability, low moisture absorption, resistance to cleaning agents and disinfectants, and resistance to sterilization processes are of central importance.

Materials such as PEEK, PPS or glass fiber reinforced PA variants are suitable for components that must function reliably over long service life cycles due to their stable material properties. Depending on the load scenario, we specifically select the combination of material and processing so that the component reliably fulfils the required function.

Our range of services

At elfo ag, we combine our engineering expertise with stable and verifiable injection moulding processes. Our range of services covers the complete development and industrialization of high-performance plastic parts for medical technology applications.

This includes selecting suitable materials depending on function, load and cleaning requirements, as well as designing parts for process stability. The design of the tool, the definition of the process window and the metrological validation are carried out systematically so that components can be manufactured reproducibly.

Through precisely controlled processes, we ensure that every series achieves the required quality and is suitable for the necessary validation steps.

Typical areas of application

High-performance plastics are particularly suitable for components in medical technology that are exposed to high thermal, chemical or mechanical stress. These include components in analysis and diagnostic systems, functional components in laboratory automation and elements in patient monitoring devices.

Materials such as PEEK or PPS offer high dimensional stability and resistance to cleaning agents and disinfectants. They are also suitable for applications that require repeated sterilisation processes. This means that even complex geometries can be realised that remain stable over long service life cycles and reliably fulfil the required function.

Why choose high-performance plastic parts from elfo ag for medical technology

elfo ag has extensive experience in processing sophisticated high-performance plastics and implementing stable injection moulding processes. For applications in medical technology, this means reproducible components with high dimensional accuracy that are suitable for validatable series processes.

High-performance plastics enable a combination of functional reliability, durability and design freedom in the medical environment. They are resistant to cleaning agents and disinfectants, produce few particles and are suitable for applications with high demands on resilience and service life. Together, we examine the requirements of your application and assess whether a high-performance plastic part offers technical or economic added value.

Here you can learn more about high-performance plastic parts and see examples of completed projects:

High-performance plastic parts | elfo ag