Five Frequently Asked Answers About Anodizing Titanium, Tantalum, Niobium, and Zirconium

Five Answers About Anodizing Titanium, Tantalum, Niobium, and Zirconium: Strength and Hardness, Coefficient of Friction, Cold Welding, and Differences Between Anodurit® C and Anodurit® S.

1. Is the strength of the components changed?

Anodizing can lead to improved fatigue curves in endurance tests. However, changes in strength are not directly measurable.

2. Is the hardness of the components changed?

The basic hardness of titanium remains unchanged. However, the surface hardness is increased compared to flat components.

3. Are there any findings on how the coefficient of friction for titanium-titanium connections changes?

We are not aware of any tribological studies on and with titanium that deal with the change in the coefficient of friction after anodic oxidation. The rubbing of two rods with and without anodization is an example at MedtecLIVE, where everyone can immediately feel the change - whether scratching (of the fresh oxide) or sliding (anodized).

4. Where does cold welding come from?

Titanium spontaneously forms an oxide film in air. This can easily be removed by movement, resulting in a fine oxide powder. Movement, for example by screwing or vibration, leads to this.

5. Difference between Anodurit® C (Type 3) and Anodurit® S (Type 2)

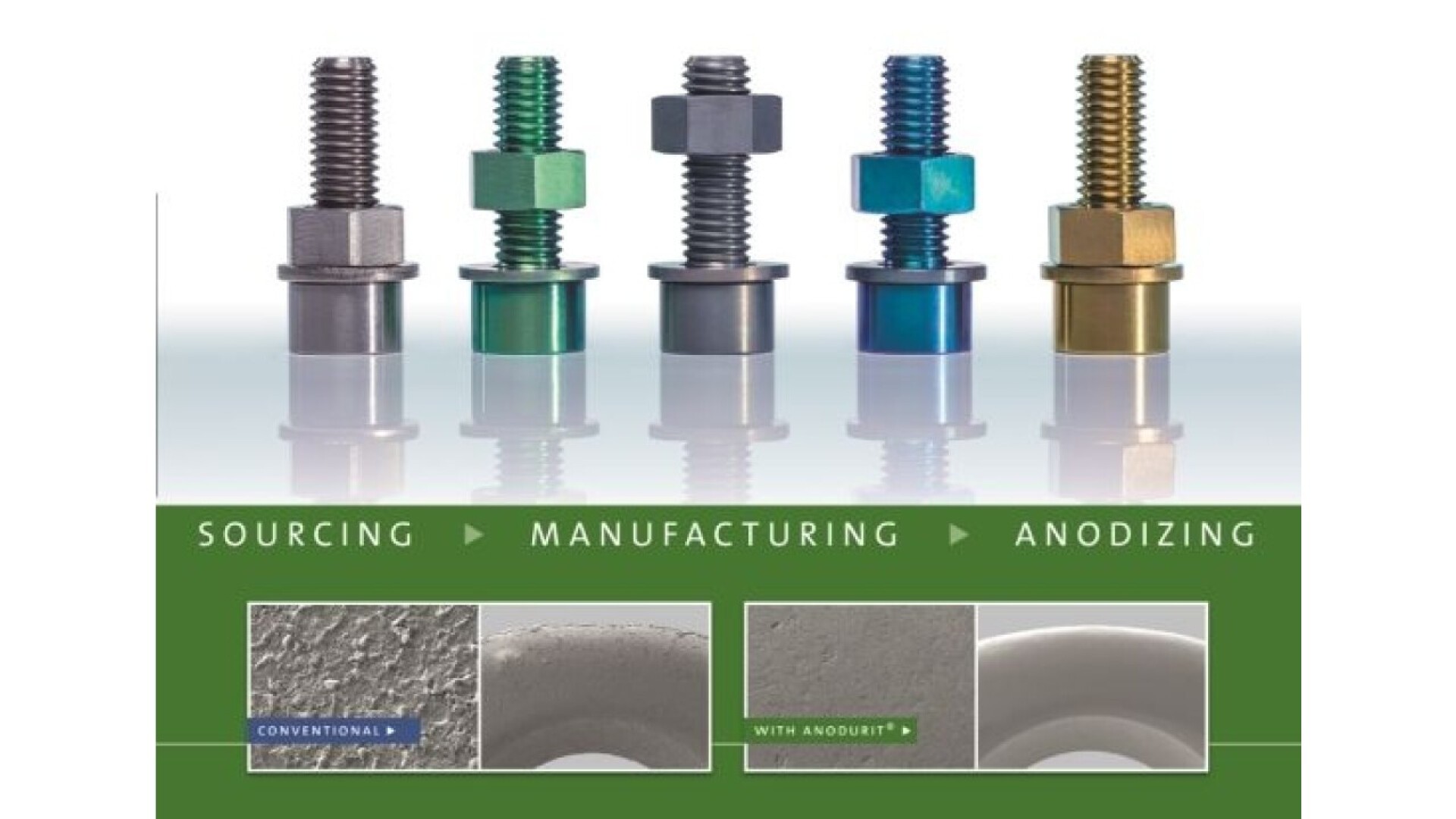

Basically, the ceramic, closed layer on the surface is formed by applying a voltage. As little as 5 VDC is sufficient. The first screw is the original version without anodization. If the applied voltage is increased - over 160 VDC - Anodurit® S is formed. The surface then appears as shown on the right in the macro images, and this without sandblasting.