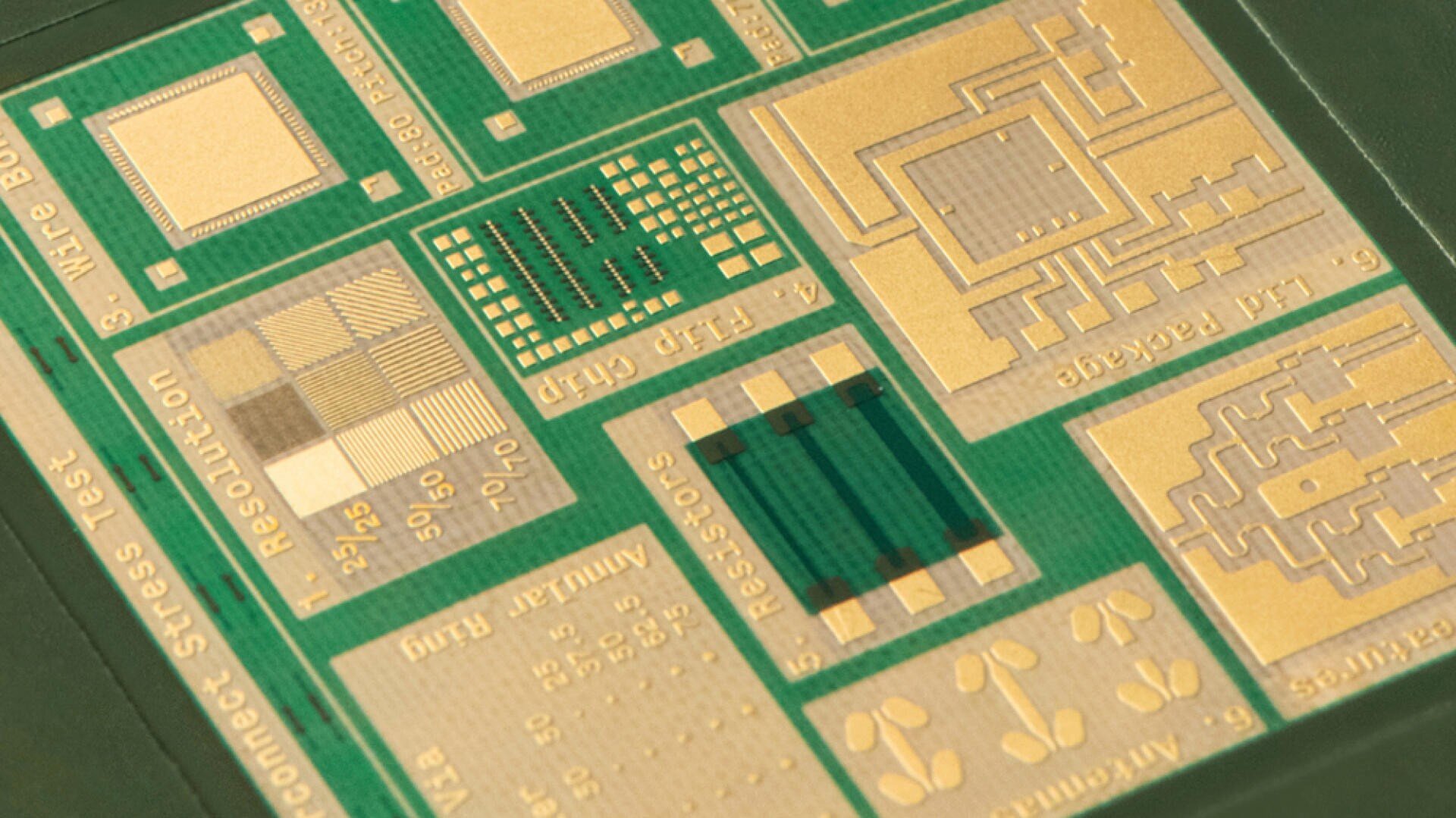

Flexible High-Density Printed Circuit Boards (HD-PCBs)

Flexible HD printed circuit boards made from polyimide enable highly precise conductor structures with exceptional bendability. Their flexible films allow folding, bending, and integration into three-dimensional device designs without compromising electrical performance.

A key aspect of such constructions is the choice of bonding system. Instead of standard prepregs, flexible acrylic or epoxy adhesives are often used, as they offer better compliance under mechanical stress and higher reliability in dynamic bend areas. This makes it possible to achieve thinner overall builds, which in turn support tighter bend radii.

For sections requiring increased stability, rigid reinforcement zones can be integrated—either as multi-flex structures or by adding glass fiber layers. These hybrid constructions combine the flexibility of polyimide areas with the robustness of rigid PCB segments.

Thanks to extremely thin flexible materials, ultra-fine structures down to 8 µm line/space can be realized, enabling modern high-density layouts. Typical bend zones range from 0.6 to 2.6 mm, depending on layer stack-up, material thickness, and application requirements.

Flexible HD-PCBs therefore open up new design possibilities, especially for compact, lightweight, and complexly shaped electronic systems.