To support medical start-ups: mapping the customer's entire value chain

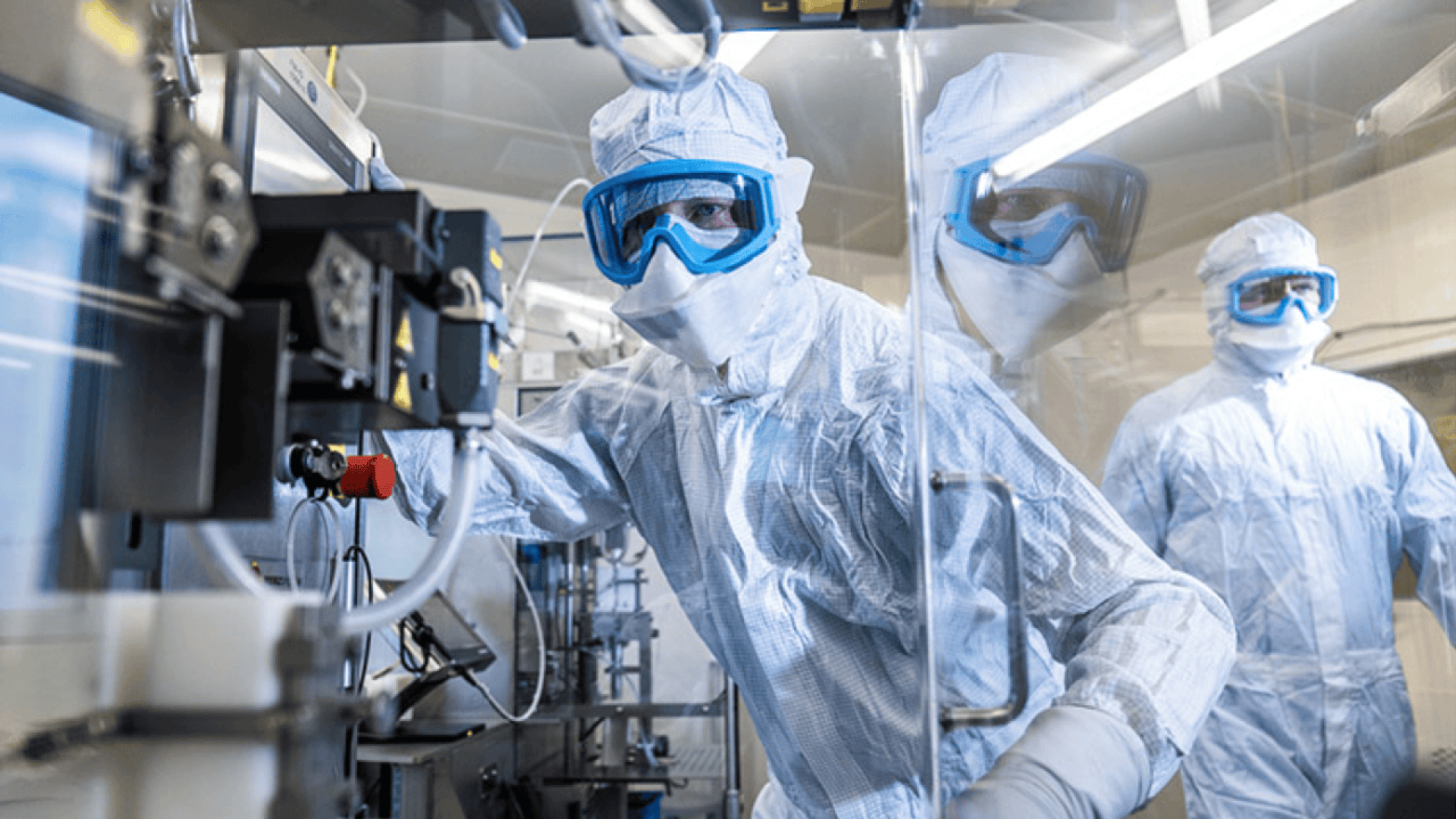

Hahn-Schickard-Gesellschaft für angewandte Forschung e. V. and Rodinger Kunststoff-Technik GmbH (RKT) have joined forces to make it easier for medical start-ups to transfer their ideas from product development to mass production. The focus is on test carrier systems and in-vitro diagnostics.

Costly and time-consuming conversions can be the result if the requirements of series production are not taken into account from the outset. The research and development service provider and the plastics specialist have now taken this experience from a number of customer projects as an opportunity to pool their expertise in future.

Focus on series production right from the start

For a successful transfer to large-scale production, it is advantageous to involve RKT already in the conception and product development by Hahn-Schickard. The research institute assists in the approval and production of the small series.

This should make the transfer to large-scale production and industrial manufacturing processes at RKT uncomplicated. "Our cooperation aims to provide the customer with the entire value chain up to the series-produced product," says Nils Paust, deputy director of the institute at Hahn-Schickard. According to Paust, the decision to have the value chain fully mapped by Hahn-Schickard and RKT lies with the customer but offers advantages.

"If we are involved in the conception at an early stage, processes can be coordinated from the outset, from the design suitable for the tool to the choice of suitable plastics," says Andreas Persch, Head of Sales and Projects at RKT. "This saves costs, because if series production is not considered from the outset, later adjustments in design, materials and processes can significantly increase the expense and valuable time can be lost in marketing the products."