Manufacturing components for the microinvasive treatment of caries

The high-quality dental materials, innovative application forms and treatment concepts from DMG Chemisch-Pharmazeutische Fabrik GmbH are used in more than 80 countries. DMG stands for quality "Made in Germany" and has found a reliable partner for component production in toolcraft.

The starting point:

Improvements in material, design and functionality

To improve the microinvasive treatment of caries using a highly liquid plastic infiltrant, DMG was in search of a new manufacturing partner to help it redesign its existing syringe and its seals. In addition to finding a new material for its sealing plug, DMG wanted to redesign the seal to improve its functionality. The company decided to entrust toolcraft with the development and manufacture of the new components.

The Challenge:

Medical components are subject to stringent requirements

The first step was to find the ideal material. The material had to be suitable for use with the special liquid infiltrant while having the necessary Shore hardness to seal the body of the syringe. Very strict component precision requirements also had to be met, with narrowly defined degrees of fit. Thermal management during the injection moulding of the 2K components also proved challenging because hard PBT components and soft TPE components must be processed at very different temperatures. Emphasis was also placed on improving cycle time to increase efficiency while simultaneously ensuring that the stringent quality requirements applicable to medical components were met.

The Approach:

Comprehensive advice and support every step of the way

- Advising the customer on the choice of materials and component design

- Assisting in the design of four parts in three different plastics (2K PBT, TPE and 1K LSR)

- Designing and making both moulds

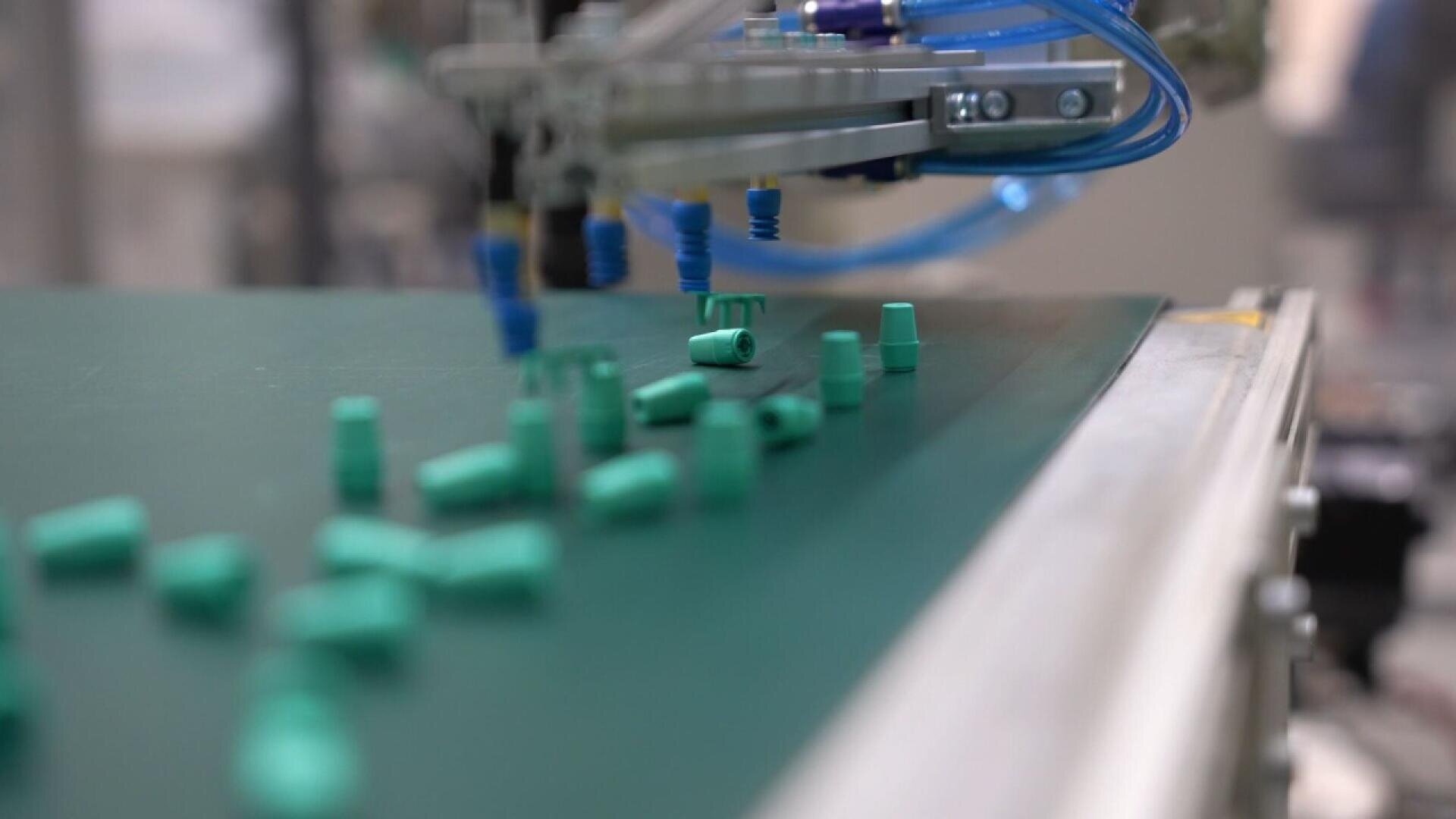

- Manufacturing the injection-moulded parts

- Sampling and separation of the components using robots, including quality control and sample testing

- Taking measurements by CT scan

- Designing and manufacturing an assembly jig to join the two components

- Assembling both components using the assembly jig

The Results:

Automated manufacturing, assembly and quality control

Thanks to toolcraft's expertise, it was possible to automate series production, component assembly and the use of CT scanning for series component testing, allowing the components to be optimised. The customer was supported closely every step of the way from the consultation and design stage right through to manufacturing and quality assurance. Colleagues specialising in mould making, injection moulding and robotics at toolcraft all worked together closely to make the project a success.

Find out more about our injection moulding + mould making here.