Laser marking: More than just a code

Laser markings offer a wide range of possibilities, from component identification and function-related markings to the individualization of consumer goods. They meet the highest requirements for traceability and counterfeit protection.

How does laser marking work?

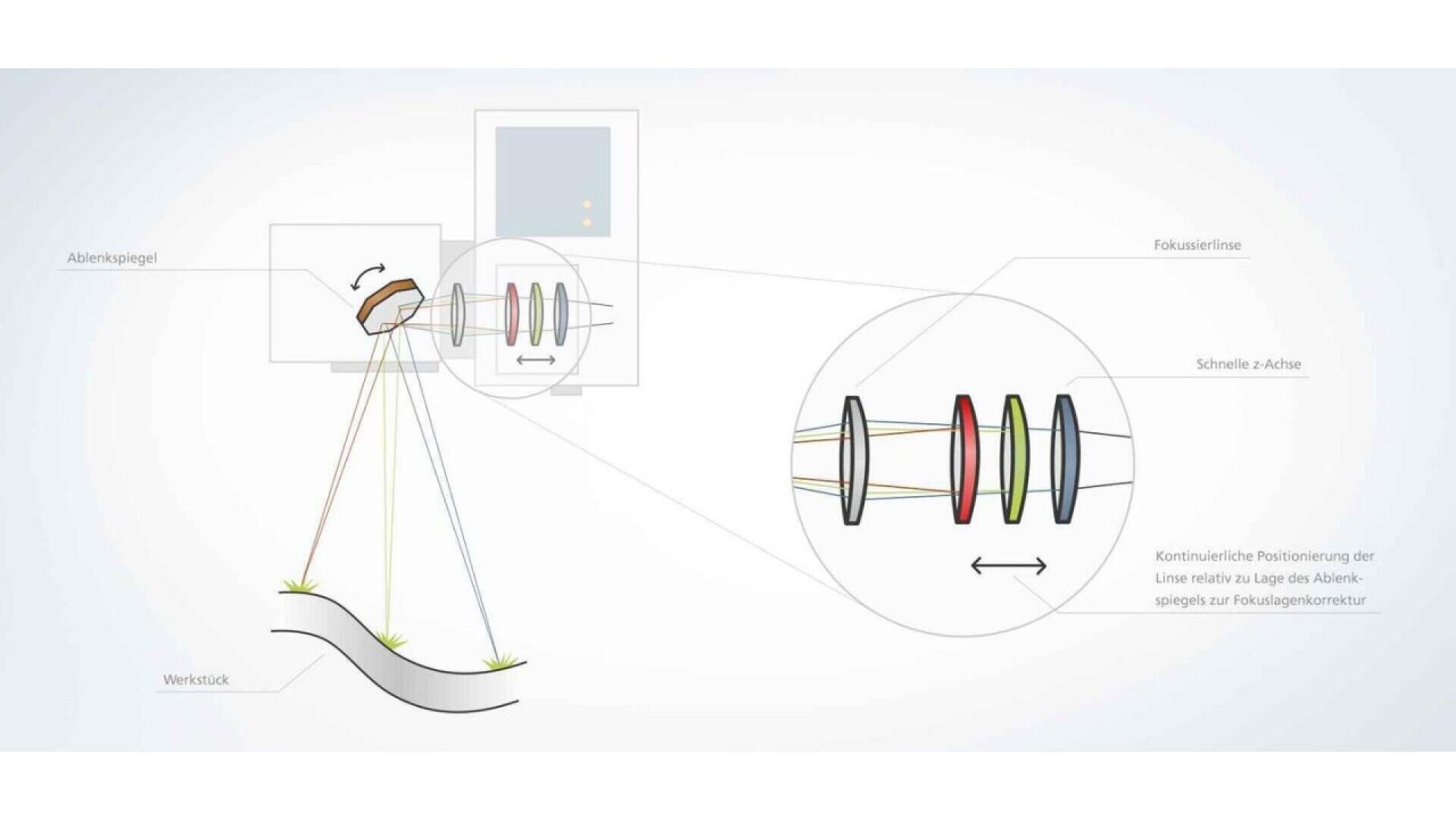

In laser marking, the marking is applied directly to the surface using an intense, pulsed laser beam. The interaction of the focused beam with the surface leads to a change in the material - for example, discoloration, structuring, engraving or material removal. How the material changes essentially depends on the wavelength of the laser, the pulse duration and the power density of the laser beam in the focus.

Processes in laser marking

Laser marking is a collective term for several processes: Tempering, engraving, black marking, color change and foaming. But which process is the most suitable? This depends above all on the material and the quality requirements of the product in question. For example, a completely different procedure is suitable for laser marking on metal than for marking plastic.

Find out more about the different laser marking processes:

Annealing

Laser marking plastic

Laser engraving

Black marking

Laser marking of copper

Laser marking of electronic components

What are the advantages of laser marking?

Marking in industry - this now increasingly means marking by laser. Because the list of advantages of laser marking is long.

Highly flexible

Whether metal, plastic or other materials: you can mark many materials and contents with a laser. Even large surfaces and hard-to-reach areas can be processed. There is also no need for time-consuming component preparation steps, such as cleaning with chemicals or polishing surfaces. The laser does this directly in a single process step.

High quality

Laser marking is characterized by high contrast and sharp edges. Even the finest structures and micro-markings can be applied with ease.

Easy to integrate

Marking lasers are easy to integrate into (fully automated) production processes and documentation systems. Direct connection to surrounding systems and databases, as well as direct inspection using an integrated image processing system, is also easy to implement.

Easy to customize

Whether design elements, names or your own markings - standardized products can easily be provided with individual features by laser.