Innovative engineering solutions for highest precision

The production of weekly blisters for chronically ill patients is still mainly carried out manually or semi-automatically. For the first time, IMSTec has developed and built a system for its customer that enables the entire manufacturing process to be fully automated, fast and safe.

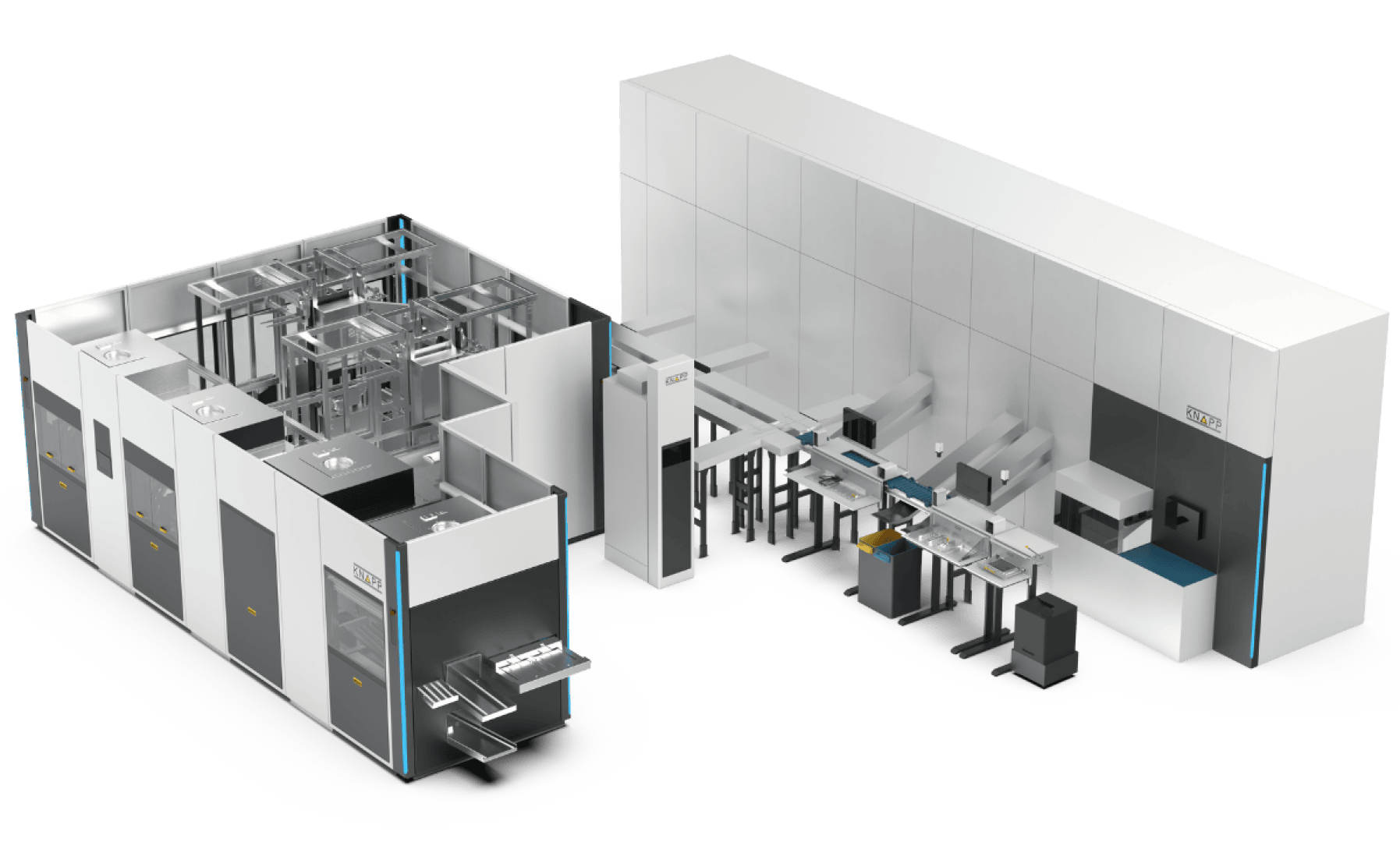

Organizing personnel structures efficiently, successfully meeting growing production requirements and ensuring maximum safety - with these demands in mind, IMSTec has implemented the first fully automated blister packaging system for KNAPP AG in Graz.

IMSTec's solution combines innovative production methods with sensory and optical inspection systems. For the first time, the system processes tablets from their original blister and automatically dispenses them into an individual weekly blister for patients.

The system is combined with an automatic picking machine and the customer's conveyor technology, which allows the degree of automation to be increased even further.

The processing of medicines is subject to the highest standards of safety, hygiene and traceability. Each process step is checked and can be viewed by the system operator. The original blisters are provided with an RFID code and can therefore be traced back to the weekly blister.

In addition to the process development and system engineering, our team of experts prepared and provided the entire technical documentation, including the required validation documents. Contamination and bacterial load tests were carried out in our own laboratories to ensure maximum quality in the final production process.

We purchase consumables from selected suppliers. This enables us to guarantee our customers consistent, high-quality products. We are driving forward our own in-house production of weekly blisters at our second site, which will sustainably optimize the supply chains for our customers.

Get to know our healthcare engineering solutions and visit us at this year's Automatica 2025 in Munich at stand 231 in hall A6.