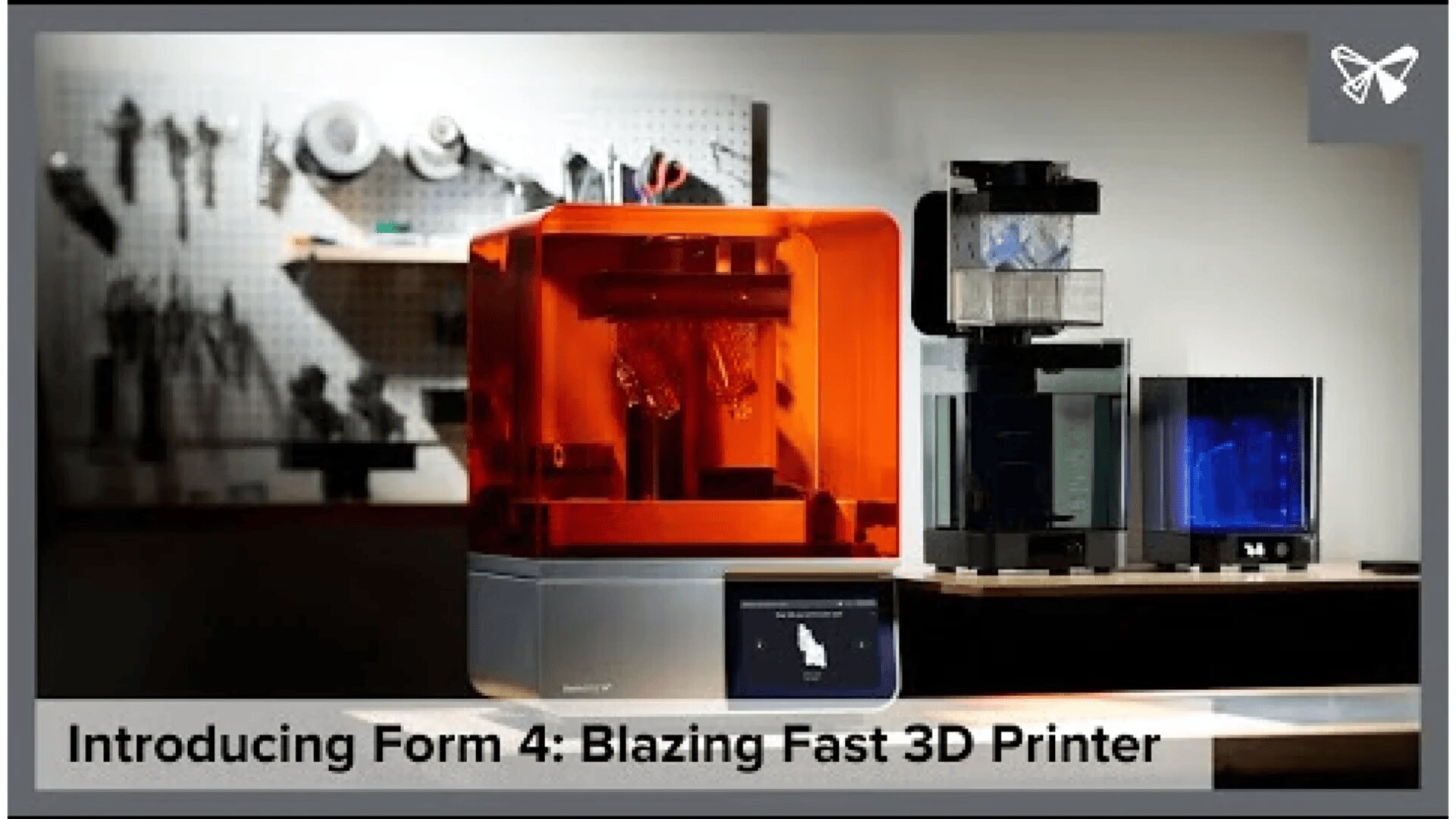

Formlabs Form 4 and 4B the stars in the field of SLA printing.

Formlabs raises the bar in 3D printing to a new level with the Form 4 and Form 4B. Formlabs, a leader in 3D printing, recently introduced two new resin printers: the Form 4 and Form 4B. Both printers are based on proven stereolithography (SLA) technology and offer a number of improvements...

... over previous models, making them particularly suitable for medical applications.

Speed and precision for the highest demands

One of the outstanding features of the Form 4 and Form 4B is their incredible speed. Both printers are up to four times faster than their predecessors and can therefore print complex models in less time. This is a great advantage for medical professionals who need patient-specific models, prostheses or surgical aids quickly.

In addition to speed, the printers also impress with their high precision. With a resolution of up to 25 micrometres, they produce detailed and dimensionally accurate prints that meet the high demands of the medical industry.

Expanded material portfolio for a wide range of applications

Along with the new printers, Formlabs has also greatly expanded its material portfolio. Both the Form 4 and Form 4B are compatible with a variety of biocompatible resins that are ideal for a wide range of medical applications. These include:

Printing of anatomical models: For pre-operative planning and training

Fabrication of patient-specific prostheses and implants: Customization for optimal fit and function

Production of surgical aids: Precise tools for minimally invasive procedures

Bioprinting of tissue and organs: research and development in the field of regenerative medicine

Form 4 and Form 4B: The future of 3D printing in medicine

The software that comes with the Form 4 and Form 4B is intuitive and easy to use. This means that even users with no 3D printing experience can quickly get to grips with the printers. The software offers a range of features that simplify the printing process, including

Automatic model alignment: the software automatically aligns the model on the build platform so that the user does not have to do this manually.

Print templates: Various print templates are available that are optimized for the most common materials and applications.

Monitoring of the printing process: The software monitors the printing process in real time and notifies the user in the event of any problems.

Form 4 and Form 4B

With their speed, precision and versatility, the Form 4 and Form 4B are setting new standards in 3D printing for the medical sector. They offer doctors, dental technicians and research institutes the opportunity to develop innovative solutions and improve patient care.

Robust and reliable printing process

The Form 4 and Form 4B are robust and reliable printers that deliver consistently high print quality. This is possible thanks to a number of design features, including

Enclosed build chamber: the enclosed build chamber protects the printer from dust and environmental conditions that can affect print quality.

High precision laser: The high precision laser ensures uniform exposure of the resin for detailed and dimensionally accurate prints.

High resolution: The printers achieve a resolution of up to 25 microns, which is ideal for creating models with fine details.

Integrated post-processing solutions:

Formlabs offers a range of integrated post-processing solutions for the Form 4 and Form 4B. These solutions simplify the workflow for creating finished models and ensure optimal results. These include:

Form Wash (Version 2):

An automatic wash system that removes excess resin from printed models.

Direct transfer from Form 4 or Form 4B: The printed parts are transferred directly from the Form 4 to the Form Wash - simply using the construction platform and without protective gloves.

Intuitive operation: Simply set the desired cleaning time and let the Form Wash do the rest.

Automatic optimization: Form Wash automatically lifts the parts out of the isopropanol (IPA) bath after the time has elapsed to prevent deformation.

Fast drying: The printed parts dry in the air and are therefore quickly available for you.

Form Cure:

A UV curing system that improves the mechanical properties of printed models.

Precise control of temperature and light: Uniform curing thanks to rotary plate and 13 multidirectional LEDs

Advanced heating system: Quickly reaches the desired temperature

Material-specific presettings: Optimal curing of every material

Fast and high-intensity curing: Up to 80°C and 405nm light

Improved performance and properties of 3D printed parts

Benefits:

- Higher strength and stiffness

- Reduced shrinkage and deformation

- Improved surface quality

- Better biocompatibility (for medical applications)

Overall conclusion:

The Form 4 and Form 4B are powerful and versatile 3D printers that push the boundaries of what is possible in the medical field. They offer a range of benefits that make them a valuable investment for hospitals, medical practices and research facilities.