Digital Twins in Medical Manufacturing: How Simulation Cuts CO2 Footprint by 70%

Manufacturers can optimize production processes through advanced simulation and finite element analysis. This technology not only increases sustainability but also improves product quality and reduces costs. Learn how this innovation is transforming the industry.

In an era where medical device manufacturers face mounting pressure to reduce their environmental impact, digital twin technology is emerging as a game-changing solution. By enabling virtual simulation of manufacturing processes, this technology is helping companies slash their carbon footprint by up to 70% during product development. This breakthrough comes at a crucial time as the medical manufacturing industry seeks to balance innovation with sustainability.

Digital Twins: Revolutionizing Medical Device Production

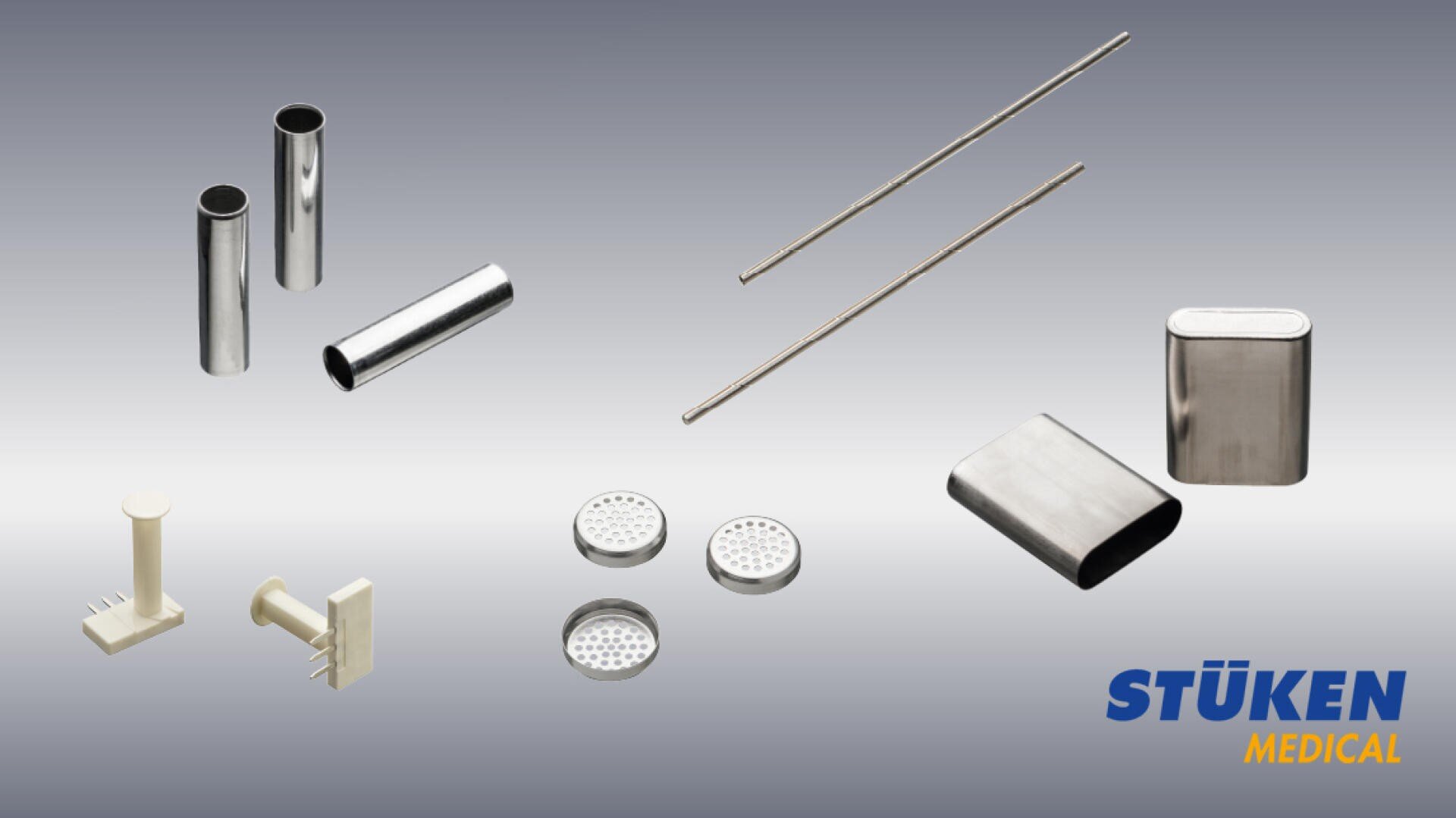

The globally active STÜKEN Group uses deep drawing, a special metal forming process, to manufacture around 100 million parts every day on over 400 presses, including a growing proportion for critical medical applications. STÜKEN MEDICAL, business unit of Hubert Stüken GmbH & Co. KG with facilities in Germany, Czech Republic, United States, China, and India, implements this technology across a diverse range of medical applications including ophthalmology, sensors, active implants, cardiovascular devices, insulin delivery systems, dialysis equipment, and dental implants. According to Andreas Hellmann, Manager STÜKEN MEDICAL, while deep drawing excels in high-volume production efficiency, it's also adaptable for low-quantity runs and prototype processes for serial applications, offering unique advantages in material usage, cost efficiency, and quality - particularly for thin-walled parts.

Digital twin technology transforms this traditional manufacturing process by creating virtual replicas of physical products and production systems. These digital models enable manufacturers to simulate and optimize production processes before any physical materials are used or tools are created.

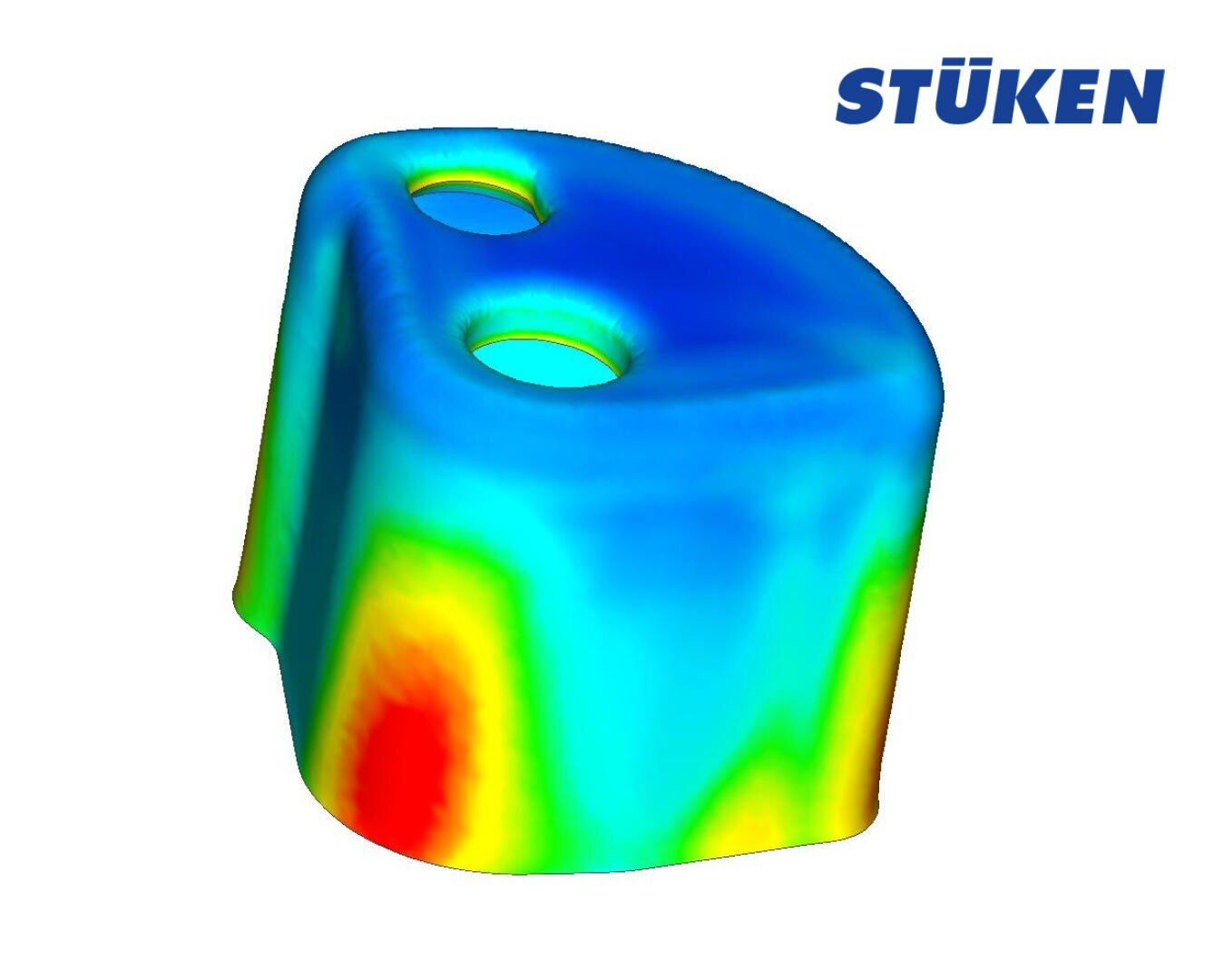

The technology's power lies in its ability to perform detailed Finite Element Analysis (FEA), which provides comprehensive insights into material behavior, stress distribution, and product performance. This virtual validation capability allows manufacturers to identify and resolve potential issues early in the development phase, significantly reducing the need for physical prototypes.

Engineering Excellence Through Virtual Validation

The FEA simulation process involves several critical steps that leverage big data approaches to continuously improve accuracy:

- Creation of robust material behavior models based on forming curves derived from metal characteristics

- Data control and preparation for simulation, including advanced parameters like temperature and lubrication effects

- Tool design and calculation (typically taking about a week for 3D models)

- Result analysis providing detailed insights into von Mises stress, material thickness, and hardness parameters

- Continuous model optimization through process data control and variable monitoring

The system creates comprehensive mathematical models that are refined with each simulation, incorporating temperature variations, tribology, and other critical parameters to enhance prediction accuracy. This iterative improvement process ensures increasingly precise results with each subsequent simulation.

Virtual validation enables manufacturers to test multiple design approaches simultaneously, optimizing everything from material thickness to spring effects in components. For example, Hellmann describes a case where simulation helped perfect an eight-millimeter diameter optical component made from hardened stainless steel, ensuring precise form and functionality without producing a single physical prototype.

The technology also facilitates closer collaboration between manufacturers and their customers. In one instance, simulation allowed for rapid material change validation from cold full steel to stainless steel within just three days, all without requiring physical material samples. This capability dramatically accelerates the development process while reducing resource consumption.

From Virtual to Reality: The Sustainability Impact

The environmental benefits of digital twin technology are substantial and measurable.

In the manufacturing of products, particularly in titanium parts for medical applications, the technology enables a 38% reduction in carbon footprint compared to traditional machined parts. These savings stem from optimizations across the entire production process, with direct emissions considerations including:

- Development process optimization

- Metal forming efficiency

- Finishing processes

- Heat treatment optimization

- Chemical treatment improvements

- Assembly streamlining

- Packaging efficiency

During the development phase, CO₂ emissions can even be reduced by up to 70% compared to conventional methods.This improvement comes primarily from eliminating the need for multiple physical prototypes and reducing material waste.

The impact is particularly significant for titanium components, where material and energy costs contribute substantially to the CO₂ footprint. Even accounting for the energy consumption of high-performance computers running week-long 3D simulations, the technology still achieves significantly lower environmental impact compared to traditional iterative physical prototyping with expensive materials like titanium.

The cost benefits align directly with environmental improvements, creating a win-win situation where sustainability initiatives directly contribute to bottom-line savings. This alignment helps make the business case for wider adoption of digital twin technology across the medical manufacturing sector.

Future-Proofing Medical Manufacturing

The implications of digital twin technology extend beyond current applications. As the medical device industry continues to evolve, this technology positions manufacturers to meet increasingly stringent environmental regulations while maintaining high quality standards and innovation capabilities.

The scalability of digital twin solutions means that sustainability improvements can be replicated across different product lines and manufacturing facilities. This scalability is particularly important for global operations, where standardized virtual validation processes can ensure consistent quality and environmental performance across multiple locations.

Conclusion

Digital twin technology represents a crucial advancement in sustainable medical manufacturing. By enabling comprehensive virtual validation and optimization, it delivers significant reductions in carbon emissions while improving product quality and development efficiency. As the industry continues to prioritize sustainability, this technology will likely play an increasingly central role in shaping the future of medical device production.

Editorial notice:

This article is based on the presentation „Sustainable Solutions for Deep Draw Metal Components with Finite Element Analysis and Digital Twins“ of Hubert Stüken GmbH & Co. KG during MedtecLIVE Innovation Expo 2025 and was created with the support of AI. The supporting programme of MedtecLIVE 2026, which will take place from 5 to 7 May 2026 in Stuttgart, also offers numerous lectures. The trade fair brings together suppliers, providers from the development and production of medical technology, OEMs, distributors and other players in the medical technology community.