CatheterFlex® - Medical Applications

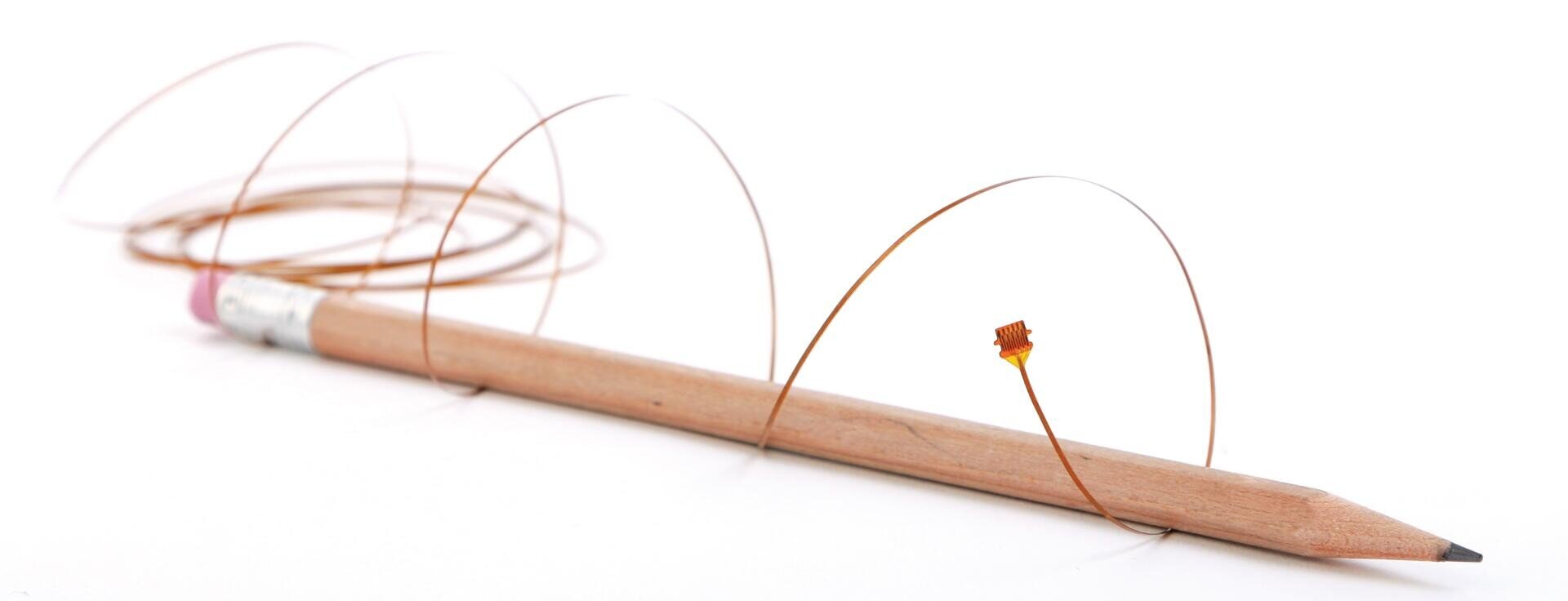

Application: Extended-length flex circuits to replace conventional wire technology in medical catheters. All Flex is teaming up with medical device manufacturers to revolutionize catheter designs.

Today's state-of-the-art designs may include small Flexible Printed Circuits (FPCs) with electrode pads mounted to the mapping baskets, but they have been limited to only 6 or 8 electrodes.

Using All Flex's innovative multi-layer CatheterFlex® technology designers can increase the density of the FPC, allowing for an increase in the electrode count (up to 64 electrodes or higher). These fine-line FPCs can run the entire length of the catheter and into the proximal handle with continuous, uninterrupted traces.

Specific Improvements Include:

Increased mapping and ablating resolution:

- Increased electrode count

- Controlled impedance

Reduced assembly cost:

- Eliminates thin wire bundle attachment

- Reduces assembly labor time

- Avoids wire entanglement and miss-connections

Increased reliability:

- Reduces the number of solder joints and material transitions

Minimal size and intrusion:

- Stacking multiple layers of FPCs without interconnects reduces the bulk that limits the minimal catheter diameter

Mainline Production

- Multi-layer construction up to 4 conductive layers

- Conductor density of 4 mil (100 µm) trace and space

- Extended length up to 64" (1.6 m) total

State-of-the-Art Advanced Circuits

- Multi-layer construction up to 8 conductive layers

- Conductor density of 2 mil (50 µm) trace and space

- Extended length up to 108" (2.75 m) total.

Disclaimer: Data presented for informational purposes only. Actual values and/or usage is for reference. Contact All Flex for details.