Before the leap into series production: Additive manufacturing is no longer limited to individual items

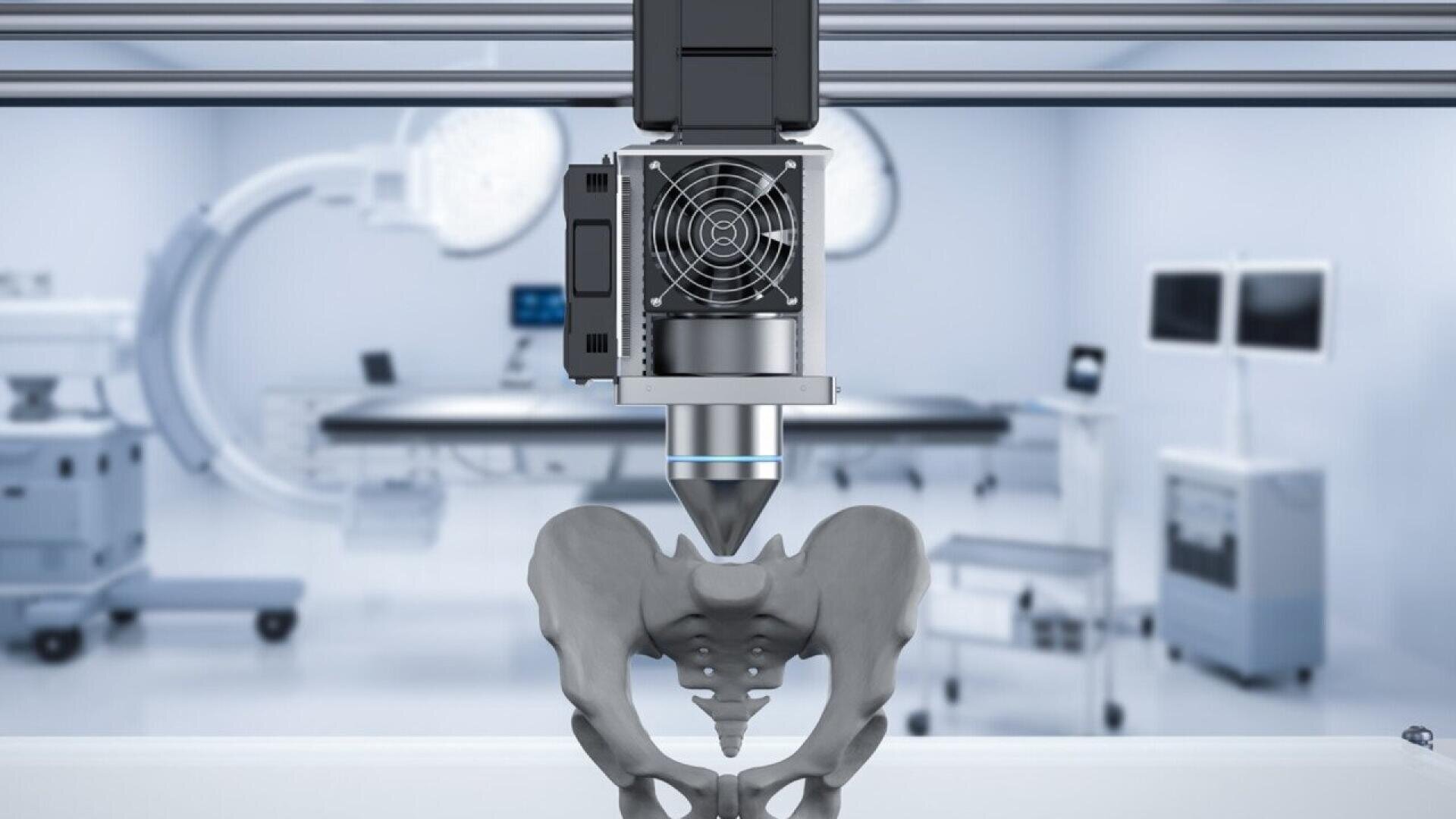

Additive manufacturing processes (also known as 3D printing) are making inroads into traditional series production. Two exciting developments are emerging: the use of additively manufactured products directly on patients and the potential for industrial use. An overview.

Additive manufacturing is considered a success story. This also applies to medical technology, where additive processes play a major role, whether for prostheses, orthoses, or dental splints. Additive manufacturing, as an industrial term for 3D printing, describes a digital production technology. In this process, layer after layer of a material is applied based on digital three-dimensional model data until the desired geometry is created. Over time, various additive manufacturing techniques have emerged that find application in various medical contexts. The breadth of application areas will be demonstrated by numerous exhibitors at MedtecLIVE with T4M in Nuremberg in May.

Plastic or metal? Both! Filament hybridisation in 3D printing

Not only can workpieces made of plastic be produced additively, with filament hybridisation a process is available for combining different materials in one system concept. This has advantages, as an additively manufactured finger orthosis vividly demonstrates.  © Lukas Boxberger | IWU

© Lukas Boxberger | IWU

Using the technology of "Wire-Encapsulation-Additive-Manufacturing" (WEAM), a team led by Lukas Boxberger, head of department in Biomechatronics at the Fraunhofer Institute for Machine Tools and Forming Technology (IWU), developed an additively manufactured finger orthosis. It is a good example of the current trend of hybridisation in additive manufacturing, "that is, the combination of different plastics, metals, textiles, and biological materials such as veneer in one manufacturing process. This makes it possible, for example, to produce patient-specific orthoses with additional electrical functions that have fluid transitions in the material structure – that is, from soft and stretchy to hard and brittle, with warming, load-sensing, or even active, adjusting functions. In this way, we are creating a technology that is capable of using every material as resource-efficiently as possible for the completion of its specific task in the composite and can thus correspond more and more to natural models. We also want to use this for more complex implants that mimic the properties of bone, adjacent tissue, and tendons and harmonise better with the biological environment," Boxberger explains. The idea is that a wire is integrated into the process. This then heats the material of the orthosis due to its electrical resistance. This becomes soft, allowing the orthosis to be individually adapted to the patient. Afterwards, the synthetic material hardens and is dimensionally stable.

The synthetic revolution of the heart: How the combination of plastic and human cells is changing the manufacture of heart valves through additive manufacturing

Additively manufactured support scaffolds are to support the growth of new tissue in the future. That was the goal of the research team led by Petra Mela, Professor of Medical Materials and Implants at the Technical University of Munich (TUM), and Professor Elena De-Juan Pardo from the University of Western Australia. Together they have developed scaffolds for artificial heart valves from the 3D printer, which should make it possible to form new tissue in the patient from the body's own cells.  Petra Mela | TUM | © Andreas Heddergott / TUM

Petra Mela | TUM | © Andreas Heddergott / TUM

These scaffolds are produced using an additive manufacturing process called melt electrowriting. This is a comparatively new additive manufacturing process that uses high voltage electricity to form precise patterns from a very thin polymer fibre. A polymer is heated, melted, and pressed out of a print head as a liquid jet. The filament the team used was medically approved polycaprolactone (PCL) because it is compatible with cells and biodegradable. After the PCL heart valves are implanted, the patients' own cells are expected to grow on the porous support scaffold, which will then form new tissue before the PCL structure degrades. "Our goal is to create bioanalogous heart valves that promote the formation of new functional tissue in the patient. Children in particular could benefit from such a solution, as currently available heart valves do not grow with the patient and therefore need to be replaced in several procedures over the years. Our heart valves, on the other hand, mimic the complexity of the body's own heart valves and are designed in such a way that they allow the patient's body cells to infiltrate the supporting structure," explains Petra Mela. © Frank Herzog | HZG Group

© Frank Herzog | HZG Group

New processes are constantly expanding the possibilities

In addition to classic technologies such as fused deposition modelling (FDM), xolography is one of a new type of process for linear volumetric 3D printing. In the former, the filament is extruded during the printing process through a nozzle that moves over a platform and builds up the model layer by layer. In xolography, on the other hand, a slice of light from light beams of different wavelengths creates the desired objects from a starting material, so that even multi-part objects can be created in one step. Until now, the limits of additive manufacturing have often been the surface finish and the low production volume. With layer-by-layer construction, metallic objects often have to be reworked. Mass production of products is usually limited by the high time and cost of printing. This is now changing thanks to xolography. "Xolography significantly improves the resolution and volume generation rate of previous processes. This means that in the future the process will be able to produce high volumes of detailed objects in a short time - the economic potential is enormous," says Frank Carsten Herzog, managing partner of the HZG Group and one of the pioneers of additive manufacturing in Germany.

What does the future hold for additive manufacturing?

Regardless of materials and processes, additive manufacturing has the potential to have a significant impact on supply chains and the healthcare system – two fields that have often presented particular challenges, especially in recent years. In particular, a combination of physical supply chain and digital process chain increases efficiency and flexibility. For example, production can be relocated independently by sending files. The dependence on physical logistics chains can be dramatically reduced. This works on a small scale and creates new opportunities in medicine as well.

For the medical technology sector, Boxberger explains, "Generative manufacturing not only offers the potential to significantly reduce supply chains, but also to disruptively transform patient care. Manufacturing centres adjacent to clinics could guarantee patient care with an individual implant directly in the operating theatre. There are already projects that show that you can, for example, scan a tooth that has just been removed and then fit the patient with a custom-fit, 3D-printed new tooth in one and the same procedure. This way, the patient would only have to be treated once instead of waiting weeks or months for a follow-up appointment. Of course, there are many other examples in the dental field or orthopaedics where the manual effort is still very high today. In my estimation, there will be significant changes in the value chain as a result of 3D printing."

The next step: additive series production

New technologies such as xolography are a step towards expanding batch sizes and improving the usability of 3D-printed workpieces. A cooperation project that aims to integrate additive processes directly into industrial series production is taking a different approach. Several partners from industry and research built two automated, additive production lines for metallic 3D printing with the BMBF project "IDEA". The Fraunhofer ILT's Laser Power Bed Fusion (LPBF) process and digital engineering along the product development chain play an important role in optimising the components. Following an intensive development and implementation phase, two automated, modular production lines were created that demonstrate the maturity of additive manufacturing as an industrial production technology. This should encourage manufacturing companies to use digital additive manufacturing in series production. The positive feedback from the operators of the lines proves that complex turbine parts with a wide range of variants and production depth can be mass-produced using the powder bed-based laser beam fusion LPBF method. © Julius Schurb | IDEA

© Julius Schurb | IDEA

Julius Schurb, project manager IDEA, from the Berlin project partner Siemens Energy gas turbine plant, says: "We were able to show for our demonstrator component, a turbine guide vane, that the planned reductions in development and throughput times of about 50 percent can be achieved by holistically considering the production chain from design to the finished product. These results will enable us to further advance the industrialisation of additive manufacturing and offer key components of our gas turbines in small quantities at competitive costs."Metallic 3D printing is also an opportunity for small and medium-sized companies. This is backed up by the experience of Toolcraft, a medium-sized company that specialises in the production of precision components and assemblies, including medical technology, and uses additive manufacturing processes for series production. © Markus Langer | Toolcraft

© Markus Langer | Toolcraft

"In the IDEA funding project, we succeeded in successfully completing important development steps, including being able to better map a holistic, continuous manufacturing chain from sub-processes," emphasises Markus Langer, Head of Digital Transformation, Research and Technology Funding at Toolcraft, and provides an overview of the project results. "Manual work steps were substituted by automation solutions, due to which a higher process stability and quality can be achieved. Digitisation should be highlighted, which must be considered globally for the production of additively manufactured components in order to be able to use real data virtually."