All Your Flexible Solutions, All In One Place

All Flex Solutions is a high quality, high reliability, customer-driven manufacturing company providing quick-turn prototype, short run, and production manufacturing of flexible circuitry, rigid flex, flexible heaters, and assembly solutions too.

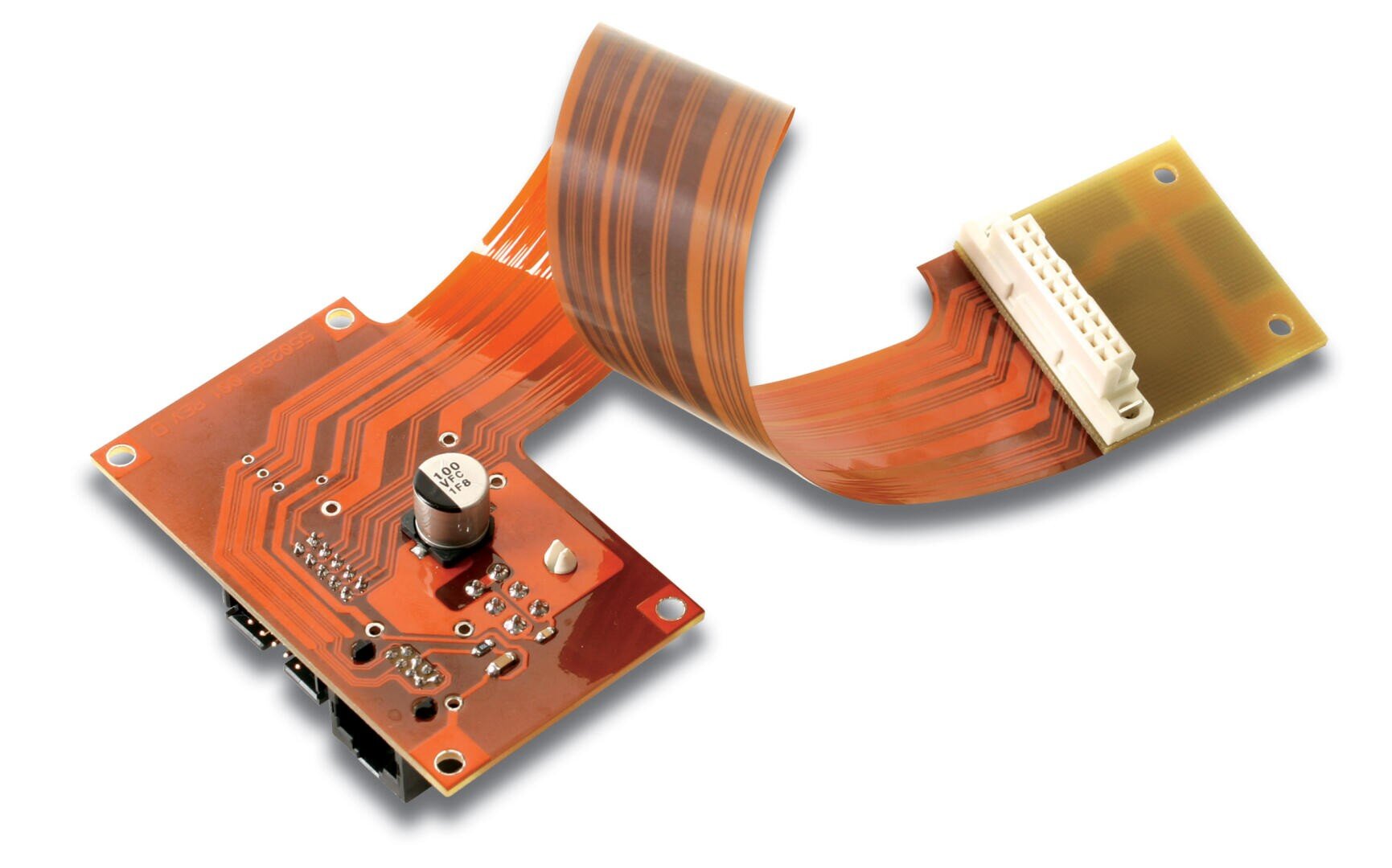

Flex Circuit Solutions

Products:

- Polyimide Flexible Circuits

- Single Sided, Double Sided,

- Multilayer Flex

- Sculptured Flex

- Maxi Flex® 40 feet+

- HighTemp Flex™

- Copper / Silver Shielding

Features:

- Tremendous flexibility in design choices

- Creates smaller, lighter, and more functional electronic packages

- Metal layer can be very thin (<.0001”) to very thick (> .010”)

- Dielectric thickness can vary from .0005” to .010”

Prototype/Quick Turn:

- First article Design Concepts

Production:

- Low to high volume production

Surface Finishes:

- EPIG, ENEPIG, ENIG

- Electrolytic nickel with hard

and soft gold - Hot, air-leveled solder

- OSP

- Immersion silver

- Immersion tin

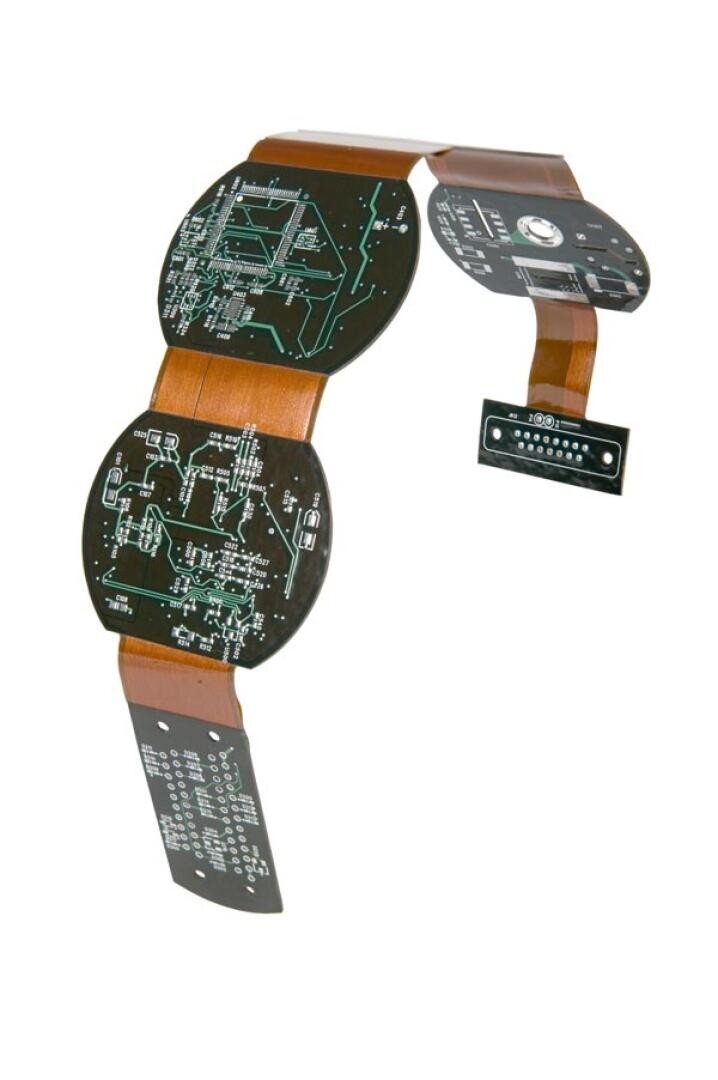

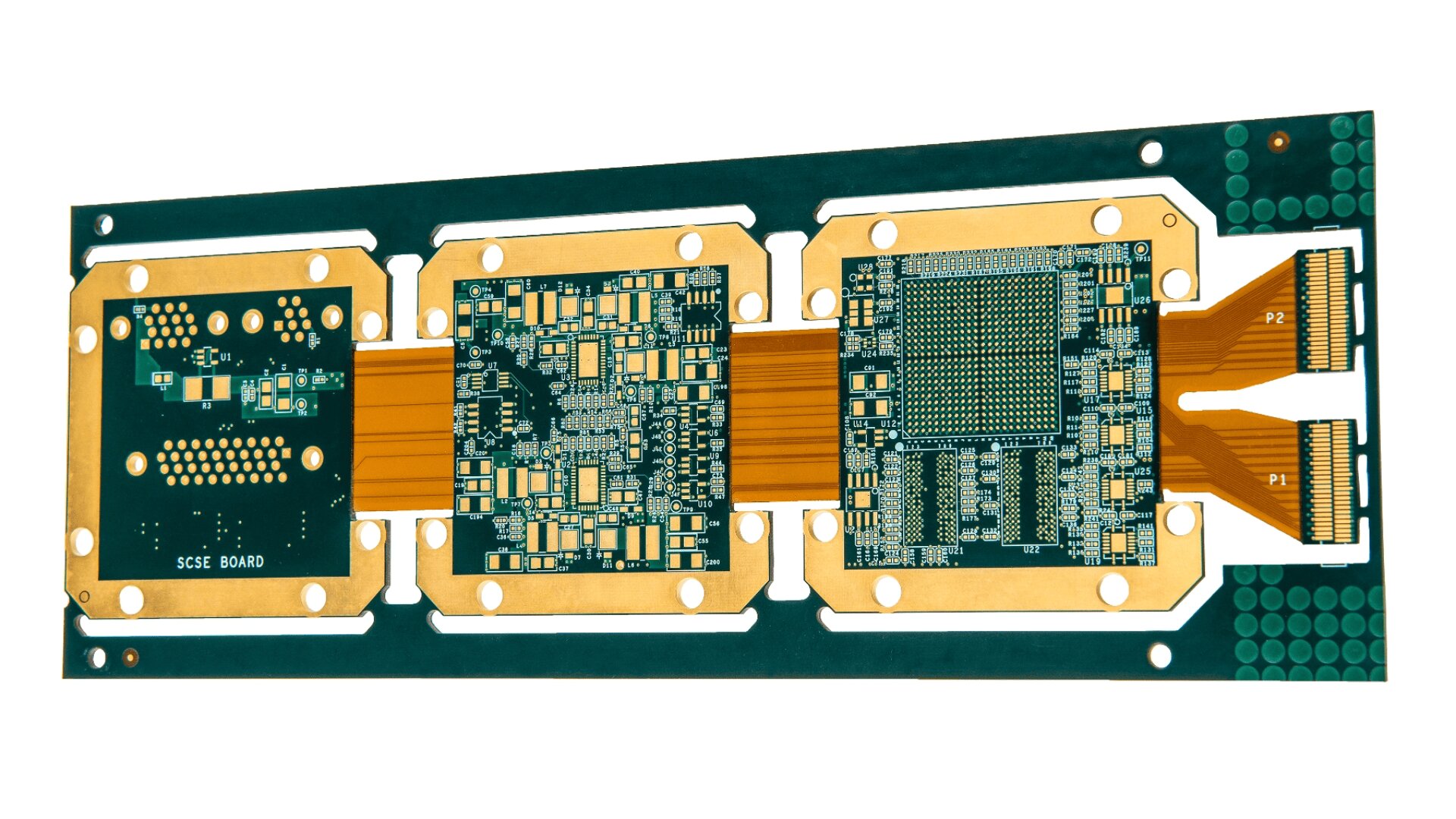

Rigid Flex Solutions

Providing the ultimate combination of circuit density with electronic packaging flexibility.

Features:

- 20 layers or more

- Dynamic and flex to install applications

- Rigid flex constructions from .012” to .145” overall thickness

- Over 85% manufactured to IPC 6013 Class III

- Adhesiveless flexible laminates from .001” to .019”

- Copper foils from 12μ to 2 ounce

- Impedance modeling, testing and reporting

- Filled conductive and non-conductive vias

- Standard UL recognized rigid flex constructions

- Unmatched survival in high shock and vibration applications

- Capable of ultra-thin, ultra-light weight packaging

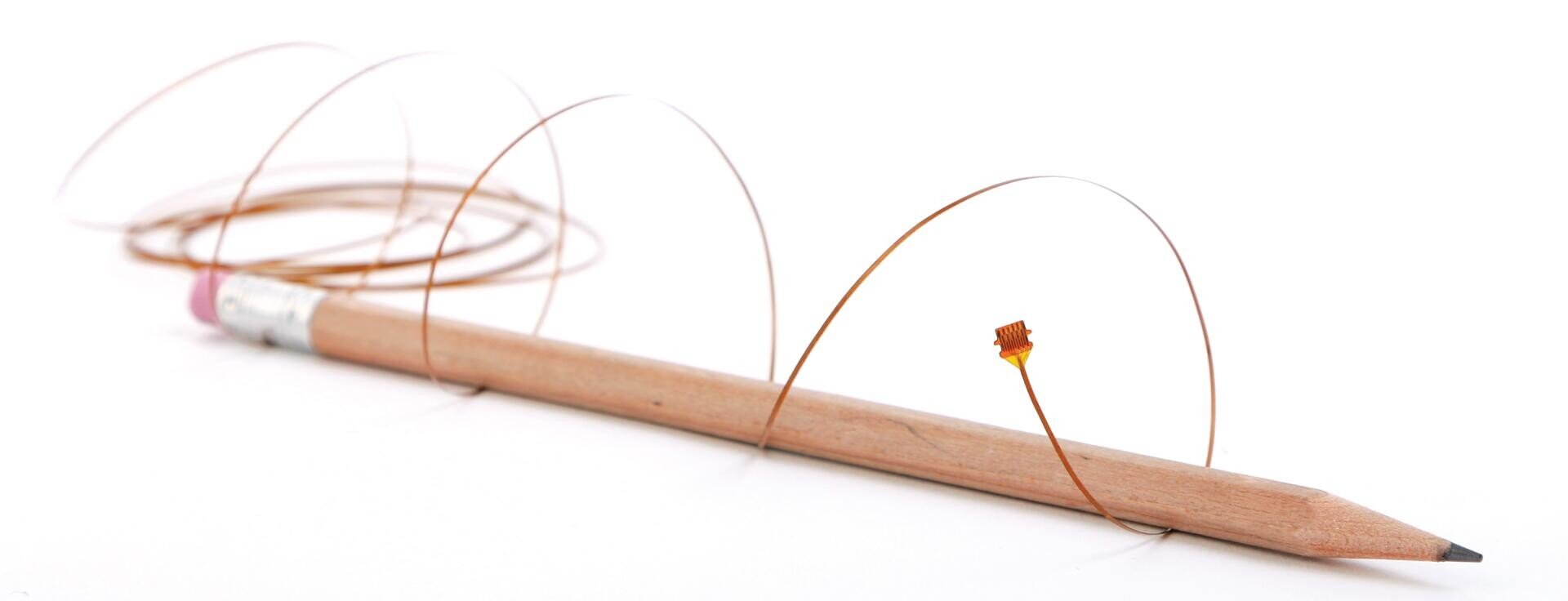

CatheterFlex® Solutions

High Density Interconnect (HDI) technology with extended length application.

Applications:

- Ablation Catheters

- Mapping / Diagnostic Catheters

- Endoscopes

Features:

- Lengths from 24” to 40 feet or more (depending on density)

- Copper trace and space down to 2-3mils (0.05-0.08mm)

- Part widths down to 10mils (0.254mm)

- Single-sided, Double-sided and even Multi-layer

- Shielding for EMI/RFI protection .019”

- Control Impedance designs

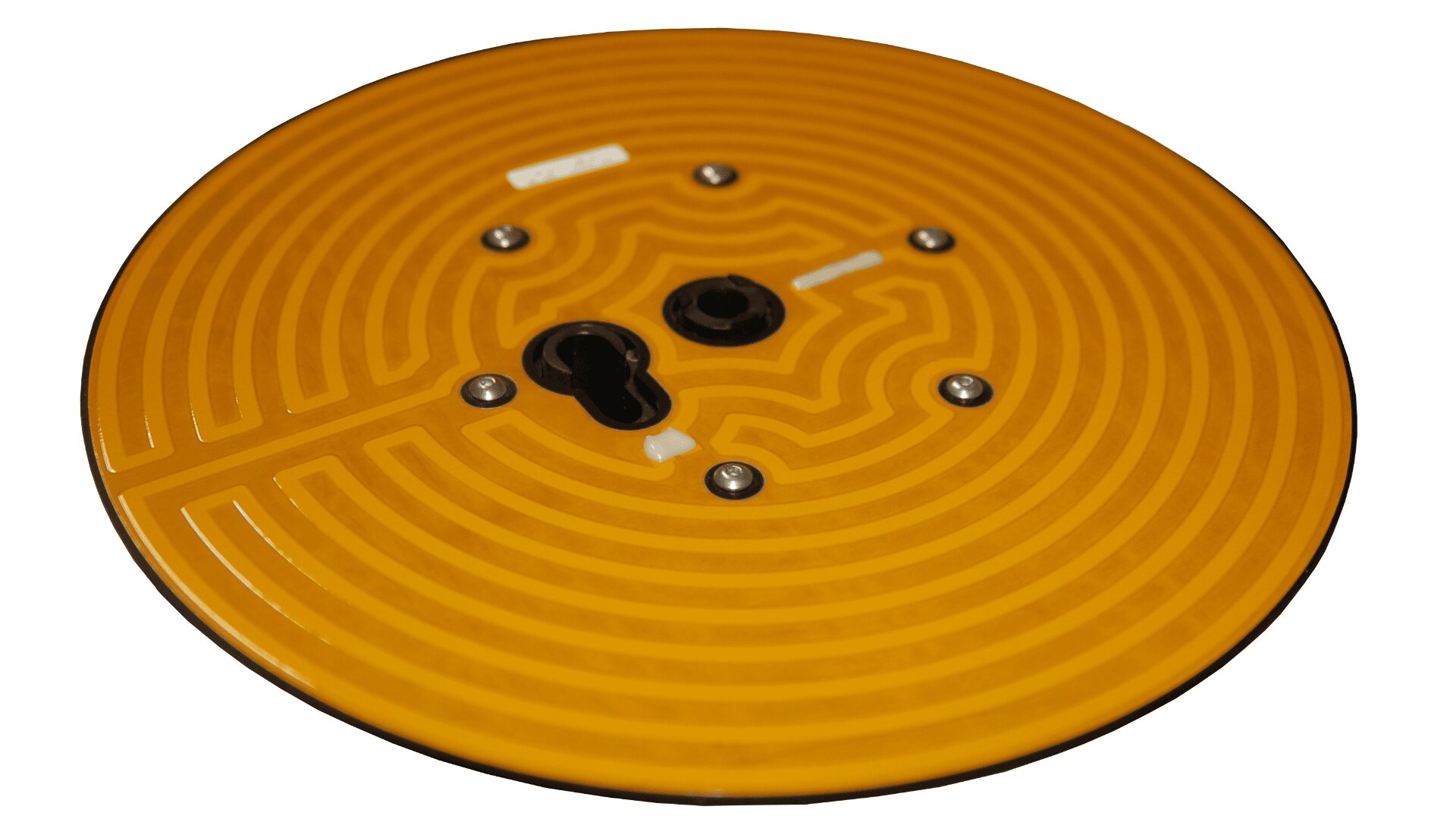

Flex Heaters Solutions

Applications:

- Temperature sensitive applications

- Extreme temperature conditions

- Freeze protection

- De-icing systems

- Heat transfer

- Heat indicator

Features:

- Polyimide & Silicone Rubber

- Custom designed into virtually any size & shape

- Integrated heaters, with flex circuit & sensors

- Direct lamination to heatsinks

- Can be built as thin as .004”

- Component & connector assembly

- Mechanical assembly

- Up to 100 watts per square inch

- Expedite Available

Stock Heaters:

All Flex also offers standard noncustom heaters without a tooling or set-up charge. A variety of sizes and shapes are available with add on options.

Assembly & Value-Added Services:

- Component assembly

- Thru Hole

- SMT

- Down to 01005

- BGAs

- Automated pick and place

- Double sided assembly

- Mixed form factor assembly

- Folding, forming

- Stiffeners

- Electrical testing

- Open/shorts

- Functional testing

- Post Assembly AOI

- Heat sinks

- Bar Coding

- Silver epoxy screening

- Wire processing/assembly

- Potting and conformal coating

- PSAs (Pressure Sensitive Adhesives)

All About All Flex Solutions

Fast Facts:

- Three Minnesota based locations

- Significant capital investment in fabrication facilities

- Continuous capital equipment investment for production expansion and quality improvement, and improved capabilities

- Average 100 new customers annually

- Support approximately 400 customers / year

- Engineering start-ups average >40 new part numbers per month

- Technical support staff includes individuals with 20+ years in the circuit board industry

- 160,000+ sq ft of manufacturing floor space

- Capable of supporting serial production volumes in addition to quick turn prototype quantities

- Military & Medical markets represent >75% of revenue for high reliability “never fail” applications ( move over)

- Three SMT assembly lines

Product Offering:

- Unsupported copper tabs

- Thick copper/power distribution circuits up to 20 mils

- Alternative metal alloys

- Polyimide dielectric films

-

Adhesive and adhesiveless materials

- Full offering of RoHS surface coatings

- High speed, fine pitch throughhole and SMT component assembly down to 0105

- Microscope soldering/assembly

- Digitally controlled nomenclature printing and product serialization

Service Offering:

- Fast quoting in 24 hours

- Full circuit design from schematic

- Reverse engineering of existing products into flexible circuitry designs

- Improved design refinement (‘flexizing’) to optimize features for flexible circuit performance and reliability

- Heater design to defined thermal output

- AOI (automated optical inspection)

- Flying probe, bed of nails and piece part electrical testing

- Consultation/design assistance

Markets Served

Medical:

- Hearing aids

- Blood analyzers

- Ultrasound equipment

- Dental instruments

- Monitors

- EP Catheters

Industrial:

- Sensors

- Measurement devices

- Heater controls

- Robotics

- Power supplies

Instrumentation:

- Data recorders

- Light and wave length analyzers

- Electronic testers

- Portable analyzers

Military/Aerospace:

- Secure radios

- Night vision

- Instrumentation

- Armament

- Unmanned systems

- Flight control hardware

- Satellite systems

Telecommunications:

- Hand-Held GPS receivers

- Modems

- Coaxial replacement

- Battery chargers

- Antennas

- Law enforcement radios

Certifications:

- AS9100 Certified

- ISO 9001 Certified

- ITAR Registered

- MIL-PRF-31032/3 Qualified

- MIL-PRF-31032/4 Qualified

- RoHS Compliant

- UL Recognized

- IPC Member

- JCP Certified