Rollon presents linear motion technology for medical technology

Efficient, precise and economical – linear motion technology plays a decisive role in product development in medical technology and laboratory automation. Rollon will be showcasing these linear technology solutions at automatica in Munich from 24 to 27 June 2025.

In addition to linear guides and actuators, ball screws, needle bearings and rod ends are also essential for the functionality and reliability of many medical devices and systems, as they offer precise control of movements and increase the service life of the devices.

Typical areas of application:

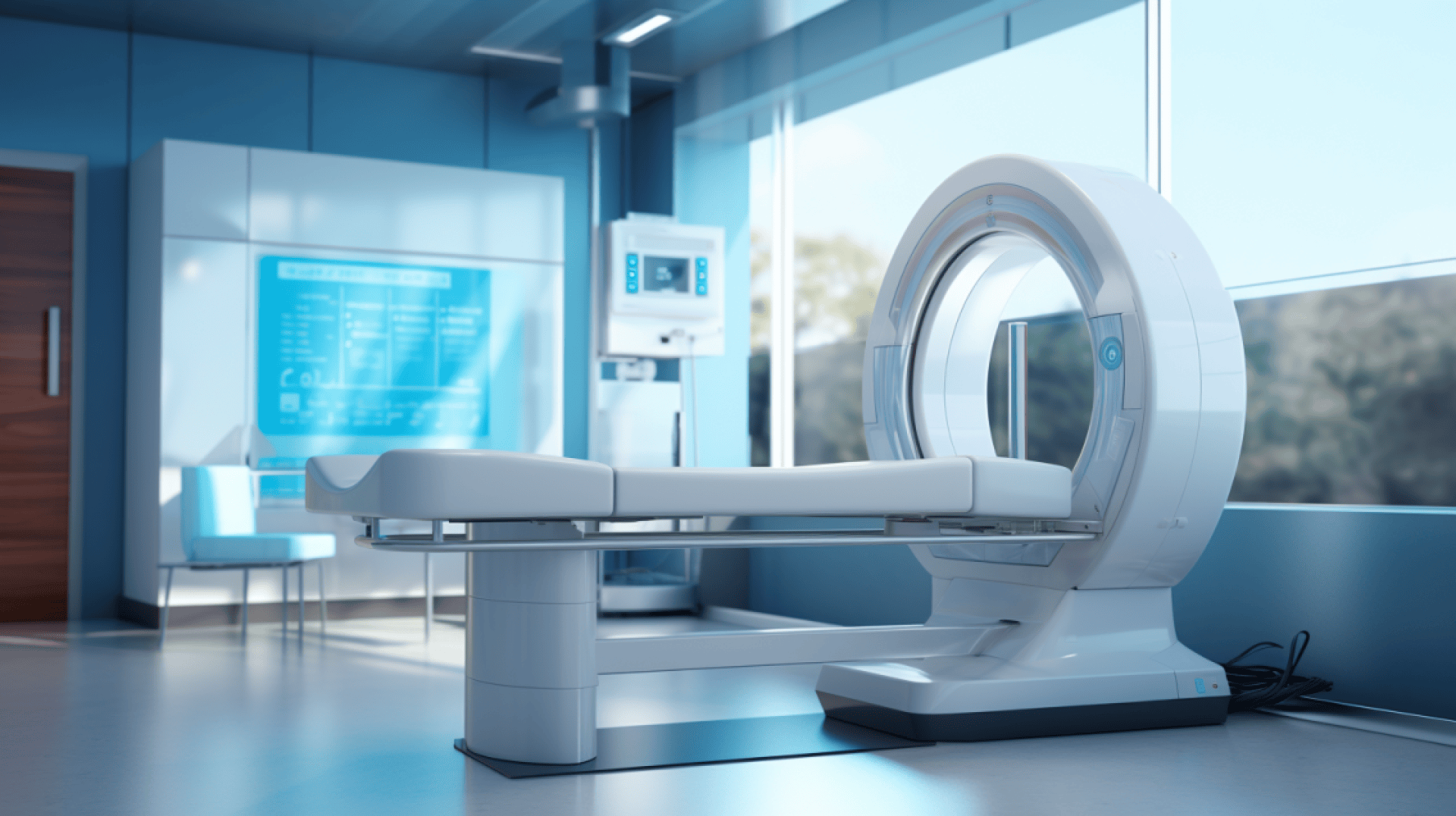

- Diagnostic devices: In machines such as X-ray and MRI devices, linear guides ensure that the movements of emitters, apertures and detectors, as well as patient beds and tables, are controlled and uniform.

- Radiotherapy equipment: Linear guides, rod ends and ball screws are used in radiation equipment to correctly dimension the radiation source and control the positioning of the beam and the patient.

- Laboratory equipment: Automated pipetting machines and sample handling systems use linear guides and actuators to transport samples precisely and reliably.

- Surgical instruments: Precisely movable components in surgical tools and robot systems use linear guides and ball joints to enable exact movements.

- Infusion and medication management: Small needle bearings stabilise the movements of rotating parts in mechanical pump systems, for example in automated infusion devices, which are used to administer the infusion solution to the patient's body at a precise rate.

- Prostheses and orthopaedic devices: In high-end prostheses and orthopaedic devices, linear guides ensure precise movements that are natural and comfortable for the user. Joint heads enable natural and flexible movement of the joints.

- Dental equipment: In high-speed dental drills and small electric drives for medical technology, needle bearings are primarily used to ensure low friction and high precision.

Complex requirements often do not call for ‘standard’ solutions. That is our speciality. Rollon works with you to develop customised solutions that meet your requirements for high precision, reliability and quality and safety standards.

We look forward to seeing you at our stand 534 in Hall B6.