Medical Components: Manufacturing Technologies

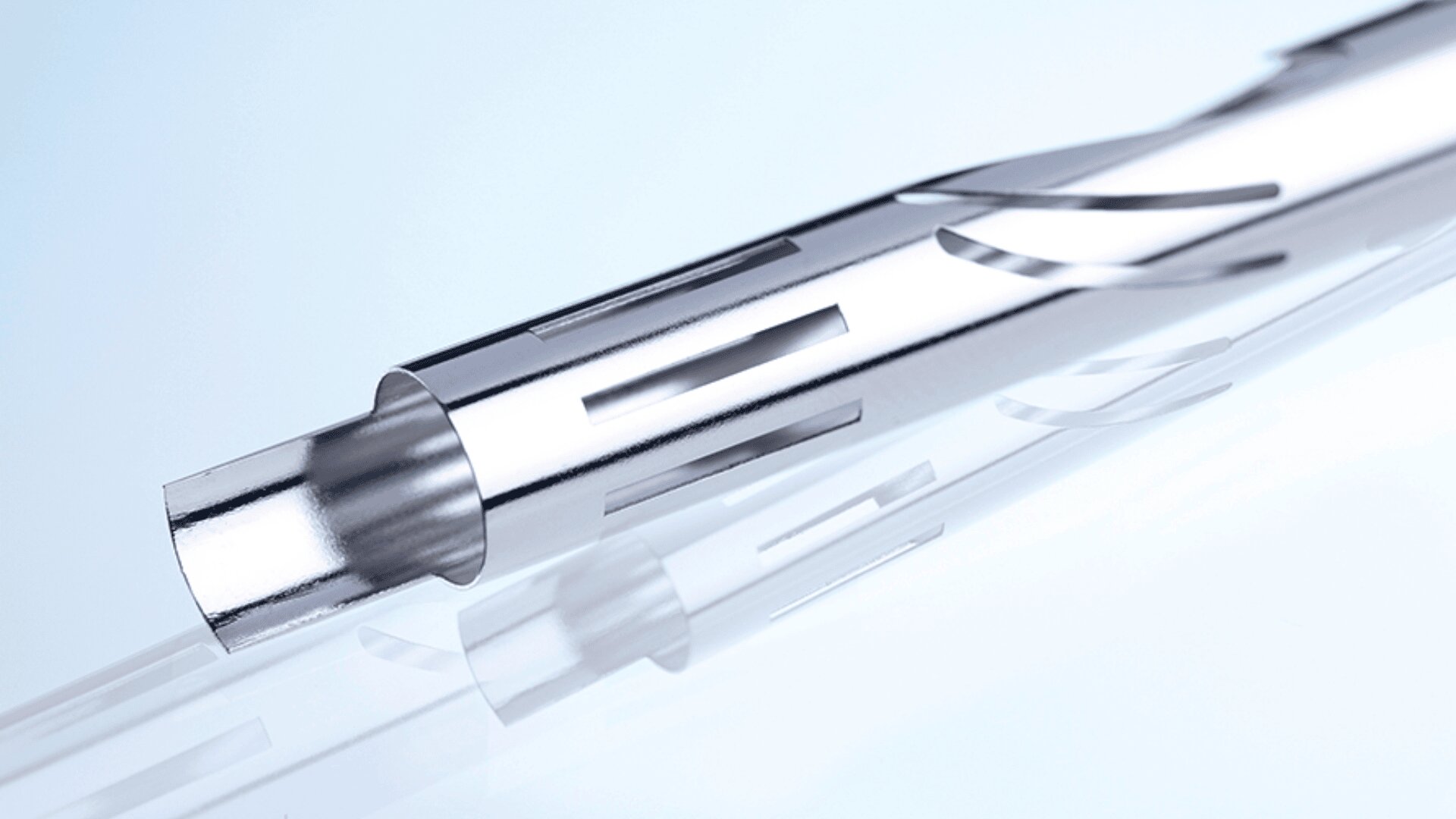

EUROFLEX offers a wide range of manufacturing processes and surface treatment options to create unique components with features including shape-forming, turned and milled parts, and laser-processed parts. Our manufacturing processes can also be tailored to customer needs.

EUROFLEX GmbH

Pforzheim,

Germany

MANUFACTURING METHODS

- 3D forming (CNC-controlled)

- Nitinol Shape-Setting

- EDM, abrasive cutting, grinding

- Laser machining (welding, cutting, marking)

- Turned and milled parts (CNC-controlled)

- Punching, deep-drawing, crimping and joining

- Profiled (non-round) tubes and wires

- (Other manufacturing methods upon request)

SURFACE TREATMENTS

- Mechanical removal methods (abrasive blasting, vibratory finishing, tumbling)

- Ultrasonic cleaning, electrolytic degreasing, etching, electro-polishing

- Laser structuring

- Galvanic surface finishing (upon request)

MATERIALS

- Nitinol

- Cobalt-based alloys (L605, MP35N)

- Stainless steel (316LVM, 316Ti, 316L, 304, 304L, 321, 17-7 PH)

- Ni-free alloys

- Titan-based alloys, Titan-grade 2

- Tantalum

- Platinum alloys (Ptlr10, Ptlr20, PtW8, PtW5)

- Resorbable alloys

- Material compounds