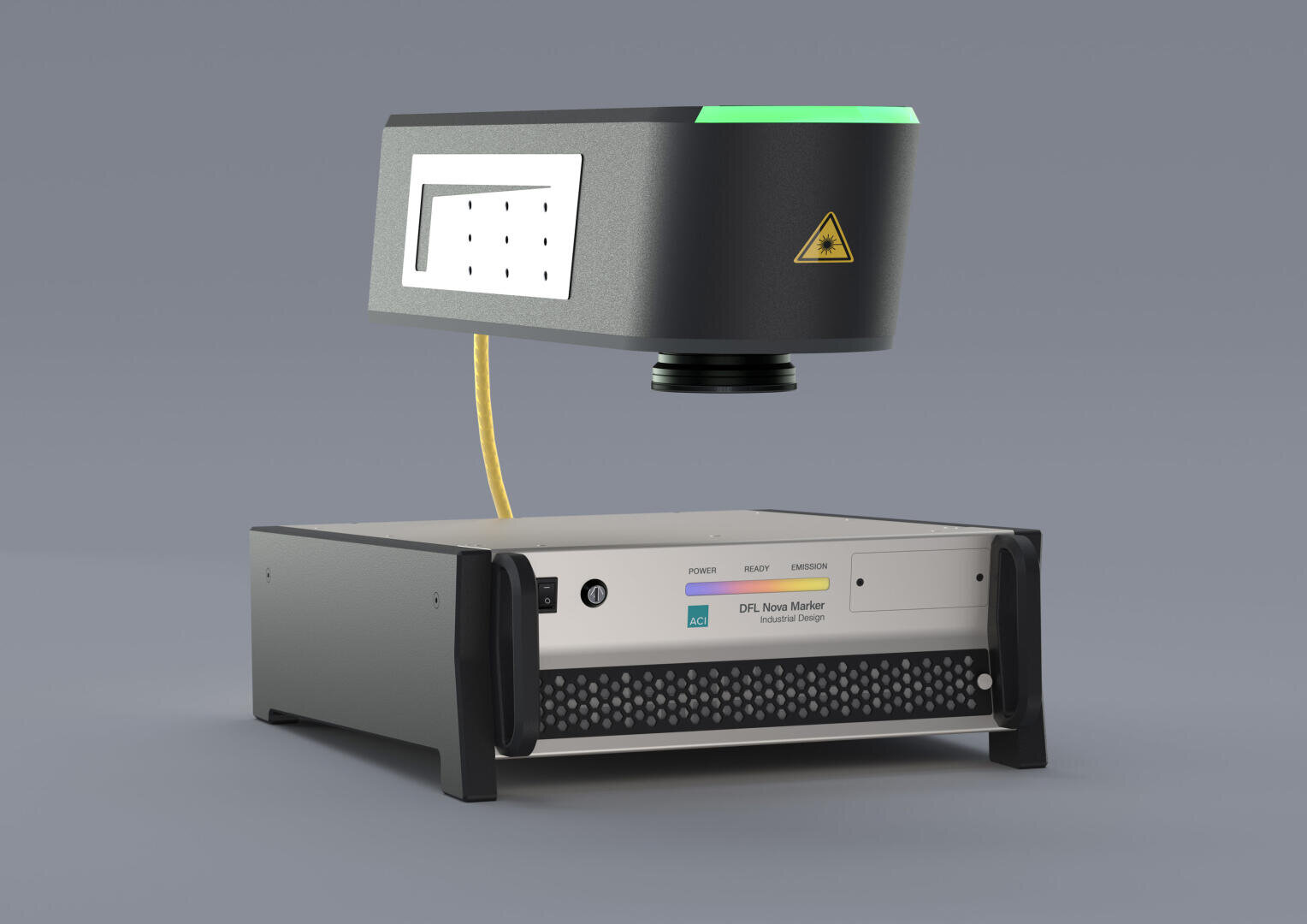

Precise material processing with the new DFL Nova Marker UV fiber laser

Gentle, "cold material processing" with powerful fiber lasers in the ultraviolet wavelength range, ideal for applications in medical technology that require maximum precision.

The DFL Nova Marker UV fiber laser was developed specifically for demanding marking and engraving applications. It stands out thanks to its versatility with different materials and is ideal for marking plastics and ceramics and for fine engraving on metals. In addition, the new UV fiber laser offers optimal conditions for high-precision fine cutting and structuring processes in medical technology. Particularly sensitive materials can be processed with the DFL Nova Marker in a contactless, permanent, and especially gentle manner.

In medical technology, the DFL Nova Marker UV fiber laser is used for permanent and durable laser marking of surgical instruments and implants. Very short laser pulses with high peak pulse powers generate high power densities, so that the material is almost immediately vaporized, a process known as “cold material processing.” Short laser pulses in the lower nanosecond range enable a wide range of materials to be processed extremely gently and cleanly. In this respect, the DFL Nova Marker is an inexpensive alternative to comparatively high-priced ultra-short pulse lasers.

The DFL Nova Marker achieves high-quality marking and structuring results on plastics and glass. Due to the wide variety of materials used in the plastics processing industry, it is important that the laser beam is well absorbed by the material. Additives, fillers, or pigments are usually added to the material for this purpose. The DFL Nova Marker produces a permanently durable marking, usually without laser additives, and thus stands out significantly from conventional infrared lasers in the wavelength range of 1064 nanometers.

The DFL Nova Marker can be used to create high-quality black markings and color transitions on ceramics. The DFL Nova Marker UV fiber laser has a clear advantage, as it can also cut ceramics. Laser engravings made with the DFL Nova Marker are characterized by burr-free edges without any burning of the material or melting marks.